16

6. START-UP

Fig. 34

6.2.

OPENING - CLOSING DIRECTIONS

Power up the system and set the opening direction on the

board (see Section 5.5.1).

I

f opening direction is to the RIGHT

(

):

OPENING limit-switch LED =

FC1

CLOSING limit-switch LED =

FC2

If opening direction is to the LEFT

(

):

OPENING limit-switch LED =

FC2

CLOSING limit-switch LED =

FC1

Note: for RF chain applications the wires on Mot1 and Mot2

(See Fig. 23) need to be reversed.

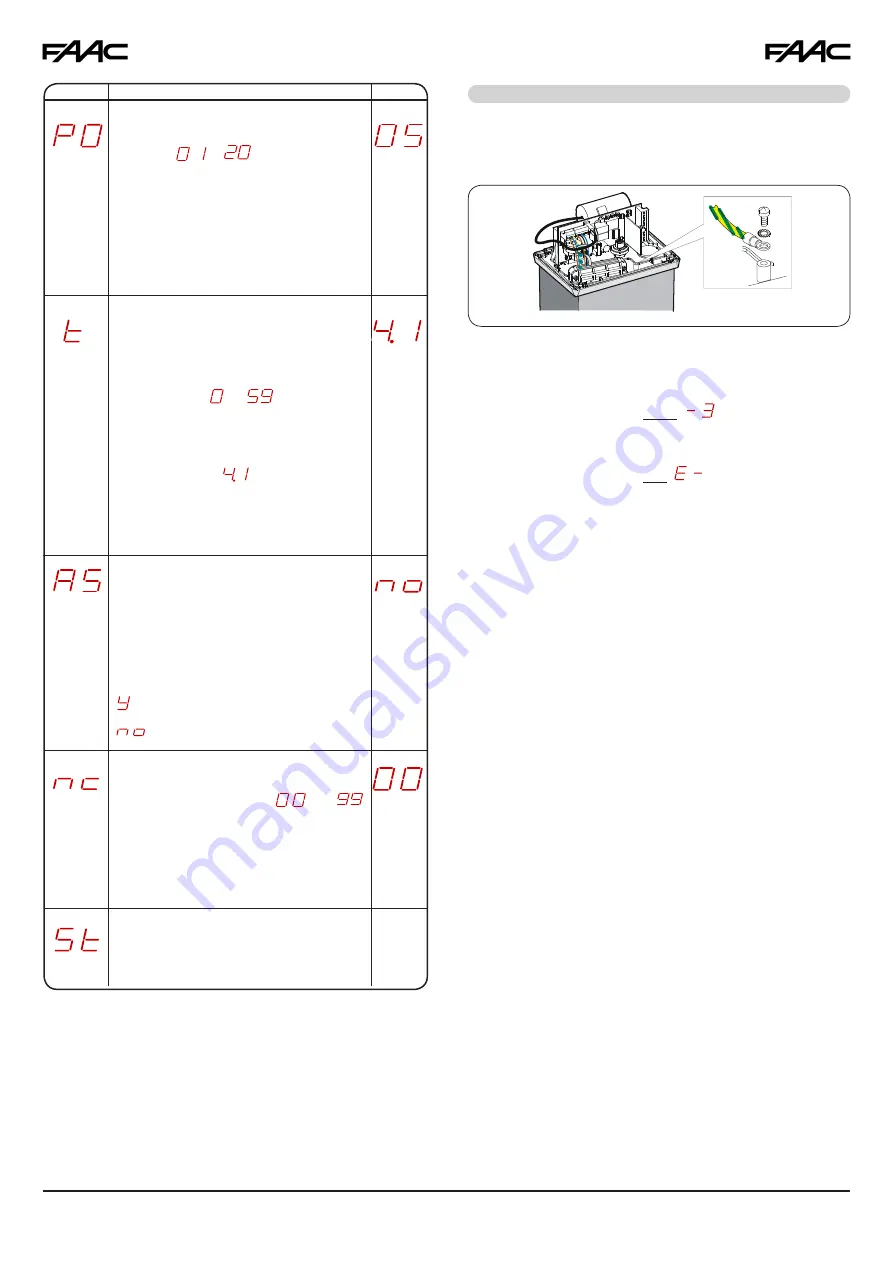

6.1.

ELECTRIC CONNECTIONS

Make all electrical connections to the board as described in

Section 5, including grounding the operator (Fig. 34).

6.3.

DETERMINING STOP POINTS AT TRAVEL

LIMIT

The 844 operator has a limit sensor switch which, by detecting

the transit of a reference applied to the rack, commands

the motor to stop. The device can be magnetic (Fig. 41) or

inductive (Fig. 42).

6.3.1.

Magnetic Limit-Switch (MLS)

The MLS limit-switch detects the transit of two magnets fitted

on the side of the rack facing the operator.

Procedure for correct positioning of the two supplied magnets:

1. Check that the operator is in manual mode (see Sec.8).

2. Manually open the gate to within 3/4 to 2 inches of the

travel limit mechanical stop.

3. Fit the magnet (without removing the protective film from

the adhesive side) on the side of the rack facing the

operator, aligning the upper edges. Slide the magnet on

the rack in opening direction until the relevant LED turns

on (Fig. 22 and 41), then move the magnet forward an

additional 1 3/4 inches.

4. Manually close the gate to within 3/4 to 2 inches of the

travel limit mechanical stop.

5. Fit the magnet (without removing the protective film from

the adhesive side) on the side of the rack facing the

operator, aligning the upper edges. Slide the magnet on

the rack in closing direction until the relevant LED turns

on (Fig. 22 and 41), then move the magnet forward an

additional 1 3/4 inches.

6. Move the gate to its halfway travel point and relock the

system (see Sec. 9).

7. Find out the desired pre- and post-limit-switch decelera-

tion values (see Section 5.5.2) and run the automated

system for at least one complete cycle.

Display

Function

Default

Note 1

: To reset the programming default settings, check

that the edge input is closed (SAFE LED ON), and

simultaneously press keys

+, -

and

F

, holding them

down for 5 seconds.

Note 2

: Modifications of programming parameters take

effect immediately, whereas changes are saved to

memory only after you exit programming and return

to normal gate status viewing. If the equipment is

powered down before returning to status viewing,

any modifications will be lost.

ASSISTANCE REQUEST (combined with

next function):

If activated, at the end of countdown (see the

next function: "Cycle Programming") it effects

2 sec. (in addition to the value already set

with the PF function) of pre-flashing at every

Open pulse (job request). It can be useful to

set scheduled maintenance jobs.

= Active

= Disabled

WORK TIME (time-out):

It is advisable to set a value of 5 to 10 seconds

over the time taken by the gate to travel from

the closing limit-switch to the opening limit-

switch and vice versa.

Adjustable from

to

sec. in one-se-

cond steps.

Subsequently, display changes to minutes and

tens of seconds (separated by a point) and

time is adjusted in 10 second steps, up to a

maximum value of

minutes.

Attention: the set value will not exactly

match the motor's maximum operating

time if decelerations are used.

PARTIAL OPENING:

You can adjust the width of partial leaf ope-

ning. from

to

.

For example, with pinion Z20, partial opening

can vary from 2' to 13'.

CYCLE PROGRAMMING:

To set countdown of system operation cycles.

Settable (in thousands) from

to

thousand cycles.

The displayed value is updated as cycles

proceed.

GATE STATUS:

Exit from programming, save data and

return to viewing gate status (see Section

5.5.1.).