Experimental Aircraft Models

- 13 -

WWW.RCHomebuilts.com

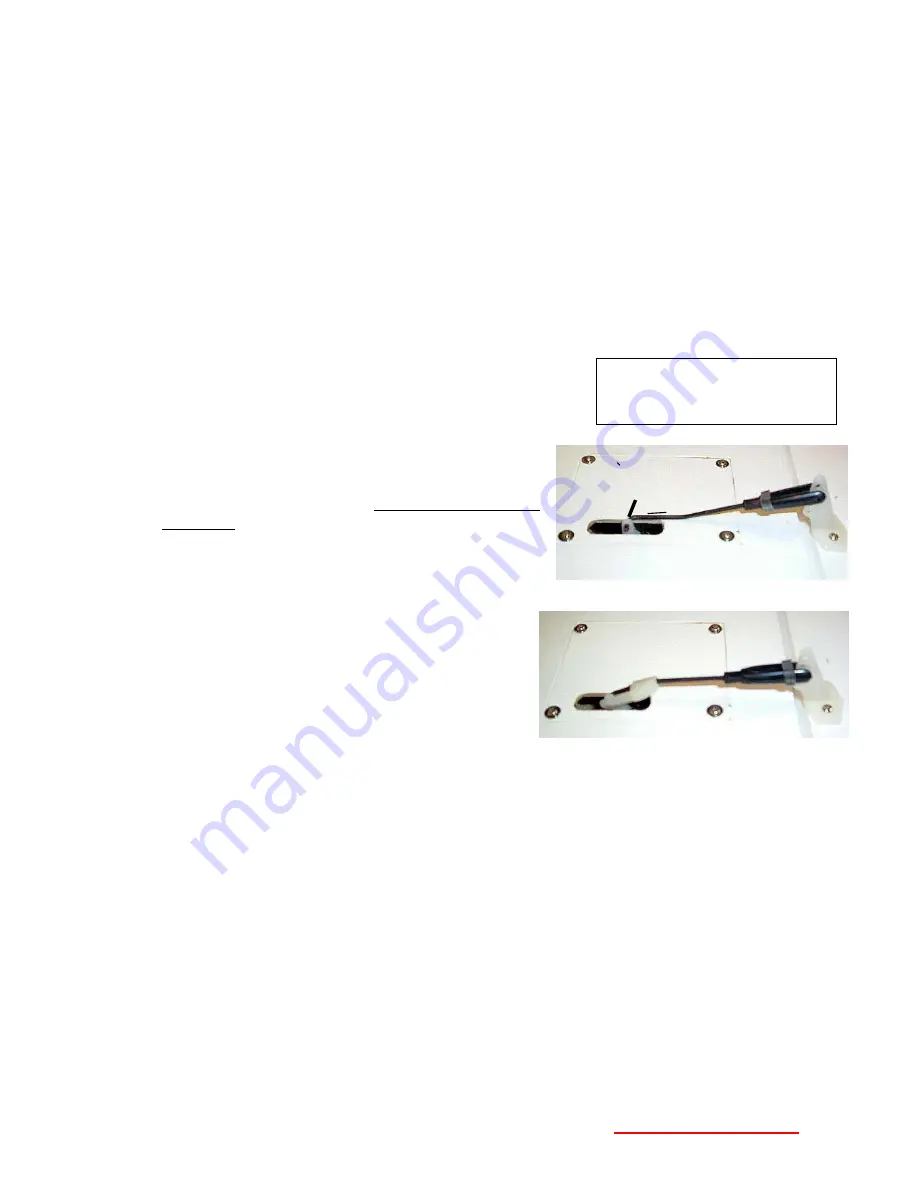

Pushrod shown already cut to length

with leg bent and upside down. Piece

gets turned over and leg inserted into

servo arm hole.

a. If you keep the rods on the right side of the servo arm on all pushrods for both wings,

the rod keepers will be more easily installed later.

b. Note that the backing plate on the topside of the wing may require sanding off the

pointed edge along one side so as not to interfere with ‘up’ aileron action.

5) To size and cut the pushrod to length, thread a clevis on to the end of a pushrod.

Temporarily attach the clevis to the horn and lay the rod along side the servo arm.

a. If you have used a short servo arm you will need to make a shallow bend in the

pushrod so that it can enter the slot and still have room for the keeper. Bend a

shallow (10 to 15 degrees) angle midway between the horn and servo arm. You will

likely have to widen the slot in the servo cover to allow room for the keeper to enter

the cover.

b. Rotate the rod 180 degrees so that the bend lays

flat along the wing – allowing you to determine

where to mark, and in the next step bend, so as

to fit the servo arm hole.

6) Mark the location of the servo arm hole on the wire

and subtract 1/16” (1.5mm) for a bend allowance.

Carefully bend a right angle (pointing away from the

servo arm!), so that when you rotate the rod back

into position it will fit into the arm. Cut the leg to

5/16” (6mm).

7) Rotate the pushrod back to the correct position and install into the servo arm using a (# 31)

Kwik Keeper.

8) Repeat the above steps to install the other

aileron servo.

9) Finish all servo installations by making sure there

is a screw securing the servo arm to the servo

and in each of the four corners holding the servo covers in place.

Canard Assembly

The canard is designed to ‘stall’ before the main wing. This is accomplished in three ways: 1) The

angle of incidence is higher than the main wing i.e. + 3.5

º

2) We choose an airfoil that stalls before

the main wing (note the sharper leading edge and thinner relative section 3) The wing loading is

higher on the canard than the main wing. You may also notice that the canard is disproportionately

heavier than the main wing(s). This is because strength is must, and weight is not a problem in the

nose of the aircraft (you’ll be adding lots of it to bring the model into balance). Similarly, the wing is

very light because much of it is behind the CG. Your Velocity’s canard has twin hardwood spars

with a double shear web and was statically stressed in development to 7 g’s. We chose to use two

small elevator servos laid on their side so that they do not interrupt the balsa bottom sheeting along

the length of the canard (helping to maintain structural integrity) and so that they fit under the canard

cover.

At the trailing edge of the canard are the elevators. These operate in unison, both moving the same

direction at the same time. They operate (almost) identically to normal elevators and control only