- 7 -

WARNING

POTENTIAL HAZARD

♦

Engine coolant is hot and pressurized.

♦

Radiator and surrounding parts are hot.

WHAT CAN HAPPEN

♦

Spray or steam from hot, pressurized liquid in the

engine cooling system or touching a hot radiator may

cause severe burns.

HOW TO AVOID THE HAZARD

♦

Allow the engine to cool completely before removing

the radiator cap or servicing any component of the

cooling system.

CAUTION

POTENTIAL HAZARD

♦

Engine coolant is toxic.

WHAT CAN HAPPEN

♦

Swallowing coolant can cause poisoning.

HOW TO AVOID THE HAZARD

♦

Do

not

swallow

♦

Keep out of reach of children and pets.

1.6 SAFETY SIGNS

1.6.1

Keep all safety signs legible. Remove all grease, dirt, and debris from safety

signs and instructional labels.

1.6.2

Safety signs must be replaced if they are missing or illegible.

1.6.3

When new components are installed, be sure that current safety signs are affixed

to the replaced components.

1.6.4

New safety signs may be obtained from your authorized Exmark equipment

dealer or distributor or from Exmark Mfg. Co. Inc.

1.6.5

Safety signs may be affixed by peeling off the backing to expose the adhesive

surface. Apply only to a clean, dry surface. Smooth to remove any air bubbles.

1.6.6

Familiarize yourself with the following safety signs and instruction labels. They

are critical to the safe operation of your Exmark commercial mower.

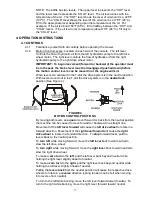

31 HP Daihatsu Gas Units Only

PART NO. 1-303293

LOCATION: On Top of Fuel Tanks

PART NO. 1-513748

LOCATIONS: Bottom Side of

Floorpan

PART NO. 103-1592

LOCATION: Top of Right Engine Baffle

PART NO. 1-323540

LOCATION: Left Rear Corner Top

of Mower Deck

PART NO. 1-513742

LOCATION: Top of Mower Deck Belt

Shields, Left and Right Sides

Summary of Contents for Laser Z XP

Page 50: ... 45 8 ELECTRICAL DIAGRAM 27 HP DAIHATSU DIESEL UNITS ...

Page 51: ... 46 ELECTRICAL DIAGRAM 31 HP DAIHATSU GAS UNITS ...

Page 52: ... 47 9 HYDRAULIC DIAGRAM ...

Page 55: ... 50 ...