Getting Started with Your Light Source

14

IQS-2150

Starting the Light Source Application

Title Bar

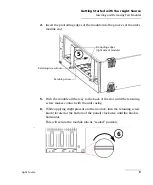

The title bar is located at the top of the main window. It displays the

module name and its position in the controller or expansion unit. The

module position is identified as follows:

Status Bar

The status bar, located at the bottom of the main window, identifies the

operational status of the IQS-2150 Light Source.

For more information about automating or remotely controlling the

IQS-2150 Light Source, refer to your platform user guide.

Slot number in which module is inserted

(0 identifies first slot)

Controller unit or expansion unit (1 to 999) housing

the module

[ 999 – 1 ]

Current date and time

Module/unit status

Local

: Module controlled locally only.

Remote

: Module controlled remotely, but

local commands can also be used.

Lockout

: Module controlled remotely only.

Control mode