Design and function

Interfaces

46

099-005214-EW501

19.05.2011

5.10.1

Automation interface

NOTE

These accessory components can be retrofitted as an option, see Accessories chapter.

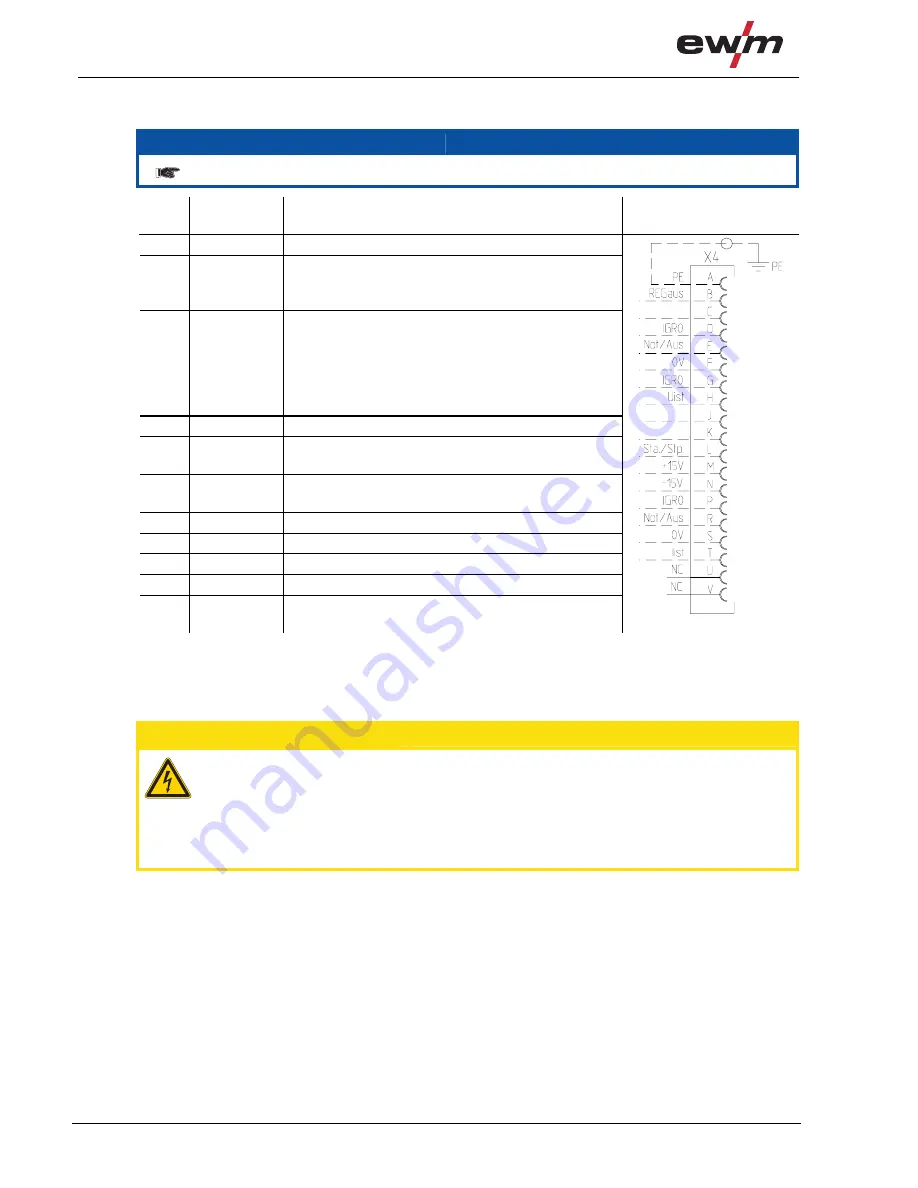

Pin Input

/

output

Description Diagram

A

Output

PE

Connection for cable shielding

D

Output

(open

collector)

IGRO

Current flows signal I>0 (maximum load 20

mA / 15 V)

0 V = welding current flows

E

+

R

Input

Not/Aus Emergency stop for higher level shut-down

of the power source.

To use this function, jumper 1 must be

unplugged on PCB M320/1 in the welding

machine. Contact open

=

welding current

off

F

Output 0

V

Reference

potential

G/P

Output I>0

Power

relay

contact, galvanically isolated

(max. +/-15 V / 100 mA)

H

Output

Uist

Welding voltage, measured against pin F,

0-10 V (0 V = 0 V; 10 V = 100 V)

L

Input

Str/Stp Start = 15 V / Stop = 0 V

1)

M

Output

+15 V

Voltage supply (max. 75 mA)

N

Output

-15 V

Voltage supply (max. 25 mA)

S

Output 0

V

Reference

potential

T

Output

Iist

Welding current, measured on pin F;

0-10 V (0 V = 0 A, 10 V = 1000 A)

1

) The operating mode is given by the wire feed unit (the start / stop function equates to pressing

the torch trigger and is used in mechanised applications, for example).

5.10.2

PC Interfaces

CAUTION

Equipment damage or faults may occur if the PC is connected incorrectly!

Not using the SECINT X10USB interface results in equipment damage or faults in signal

transmission. The PC may be destroyed due to high frequency ignition pulses.

• Interface SECINT X10USB must be connected between the PC and the welding machine!

• The connection must only be made using the cables supplied (do not use any additional

extension cables)!

PC 300 welding parameter software

Create all welding parameters quickly on the PC and easily transfer them to one or more welding

machines (accessories: set consisting of software, interface, connection leads).