31

clicks into position (this is when the tabs at points ‘

A

’ are located

in the groove of the vertical flue connector - see fig. 18). Both

screws (

C

) should now be tightened.

NOTE:

If more convenient, the vertical flue connector can be

attached to the vertical flue terminal/extension before connecting

it to the appliance.

vertical

connection

A

A

C

C

B

flange installed

as standard

Fig.18

NOTE

Additional bends and/or extensions can be connected to the

terminal connector if desired, however if additional bends are

fitted, a reduction must be made to the maximum flue length

(see table below).

Reduction for bends

Bend

Reduction in maximum flue length for each bend

45º bend

1.0 metre

90º bend

1.0 metre

Vertical flue terminal and accessories

Code

Description

Length

20122763 Vokera XV Vertical Flue kit

1000mm

29450123 90-degree bend

N/A

29450124 45-degree bends (2)

N/A

29450125 500mm extension

500mm

29450126 1000mm extension

1000mm

29450127 2000mm extension

2000mm

29450128 Telescopic extension

372/519mm

529

100mm flue brackets (5)

N/A

531

Pitched roof flashing

N/A

532

Flat roof flashing

N/A

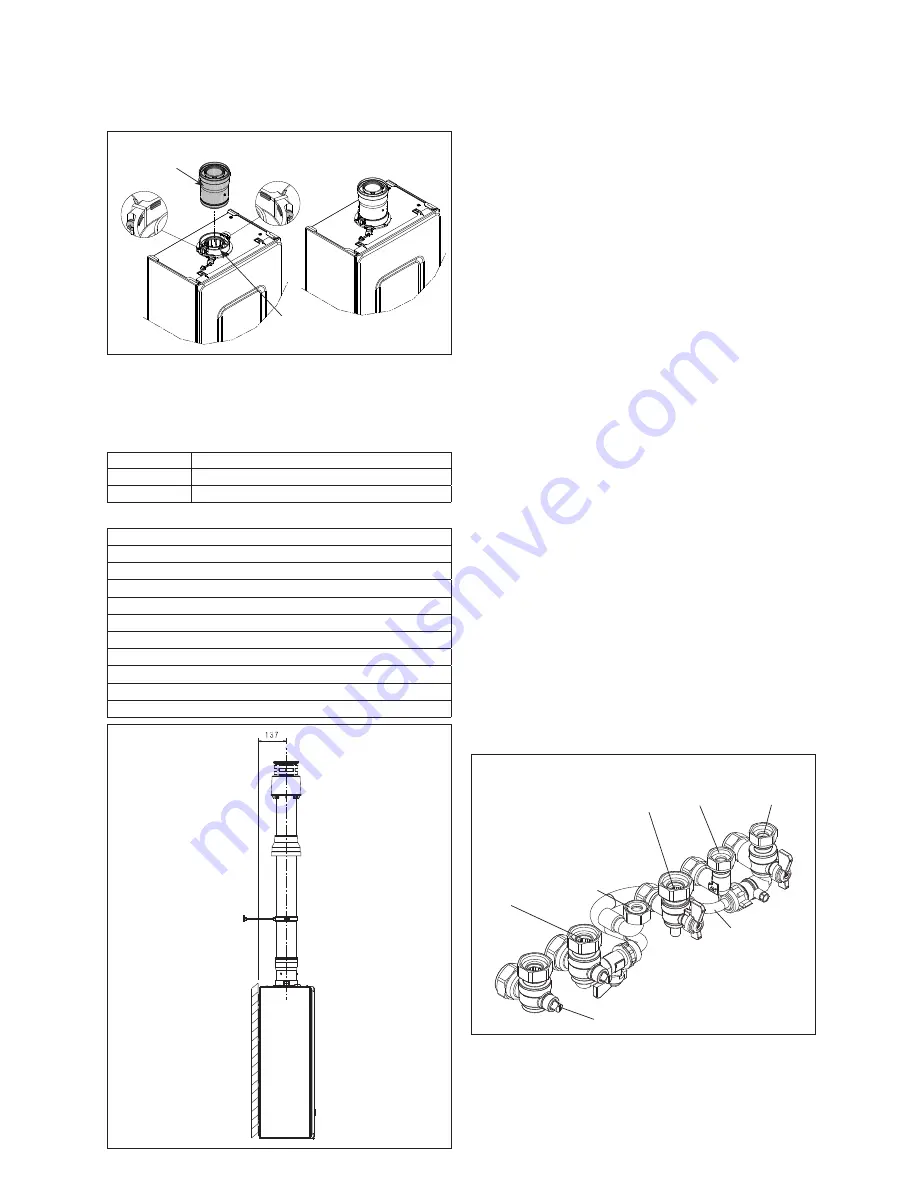

Fig. 19

IMPORTANT

The vertical flue terminal is 1.0 metre in length and cannot be

cut; therefore it may be necessary to adjust the height of the

appliance to suit or use a suitable extension.

5.6 CONNECTING THE GAS AND WATER

The appliance is supplied with an accessory pack that includes

service valves. The service valves are of the compression type.

The accessory pack contains sealing washers’ etc, for use with

the service valves. When connecting pipe work to the valves,

tighten the compression end first then insert the sealing washers

before tightening the valve to the appliance.

NOTE

It will be necessary to hold the valve with one spanner whilst

tightening with another.

5.6.1 GAS (fig. 20)

The appliance is supplied with a 15mm service valve, connect

a 15mm pipe to the inlet of the valve and tighten both nuts.

NOTE

It will be necessary to calculate the diameter of the gas supply

pipe to ensure the appliance has an adequate supply of gas.

5.6.2 FLOW & RETURN (fig. 20)

The appliance is supplied with 22mm service valves for the

flow and return connections, connect a 22mm pipe to the inlet

of each valve and tighten both nuts.

NOTE

Depending on system requirements, it may necessary to increase

the size of the flow & return pipe work after the service valve

connections.

5.6.3 COLD WATER INLET (fig. 20)

The appliance is supplied with a 15mm combined stopcock and

filling valve, connect a 15mm pipe to the inlet of the stopcock

and tighten both nuts.

5.6.4 HOT WATER OUTLET (fig. 20)

The appliance is supplied with a 15mm outlet connection, connect

a 15mm pipe to the outlet connection and tighten both nuts.

5.6.5 SAFETY VALVE (fig. 20)

Connect the safety valve connection pipe to the safety valve

outlet and tighten. The discharge pipe must have a continuous fall

away from the appliance to outside and allow any water to drain

away thereby eliminating the possibility of freezing.

The discharge pipe must terminate in a position where any water

- possibly boiling - discharges safely without causing damage or

injury, but is still visible.

Fig. 20

Hot water

outlet

Cold water

inlet

stopcock

C/H return valve

C/H flow

valve

Safety valve

outlet

Gas

cock

Filling loop

5.6.6 CONDENSATE DISPOSAL

This appliance will - under normal operating conditions - produce

condensate fluid that will require to be disposed of via the

dwelling’s waste water drainage system.

Vokera strongly recommends that the condensate pipe is

connected to the internal waste water pipework in accordance

with BS6798.