13

MAINTENANCE

LETHAL VOLTAGES PRESENT. RISK OF ELECTRIC SHOCK.

AFTER REMOVING POWER FROM THE UNIT, THE AUTOMATIC BLEEDER RESISTORS WILL

DISCHARGE THE UNIT TO 50 V IN FIVE (5) SECONDS.

USE A SHORTING STICK (NOT INCLUDED) TO TOUCH ALL METALLIC SURFACES

EXPOSED BEFORE TOUCHING THE FILTER.

Only qualified personnel should operate or service this equipment.

Periodically power down the filter and remove the wiring compartment lids to check inside for dirt, debris and corrosion.

Oil, dirt, debris and corrosion inside the filter compartments should be removed according to appropriate procedures.

User’s own procedures for the removal of spills, dirt, debris and corrosion should suffice. Should EMI gasket become

torn or unusable, contact ETS-Lindgren to order replacement part E-903-008 or E-903-016, depending on the

size of filter.

The MOV arrestor (if provided) should be replaced annually, when it is estimated that a high incidence of over voltages

have occurred during that year.

Once a filter is properly installed it typically does not require maintenance under normal operating conditions. However,

if there is an extraordinary event affecting the filters (such as a severe voltage overload or water entering the wiring

compartments), then the following procedures should be followed depending on the nature of the event. Follow the

INSPECTION AND CLEANING OF WIRING COMPARTMENTS procedure after an event that causes abnormal

contamination of filter wiring compartments with liquid or debris. Follow the CAPACITANCE MEASUREMENT AND

MOV INSPECTION PROCEDURE following an event that causes abnormal voltage overloads or spikes beyond that

which the filters are designed to accommodate.

Frequency of maintenance is at the discretion of the user and may be included in a routine maintenance

schedule for the connected equipment. However, filters in clean, industrial environments typically do not

require maintenance.

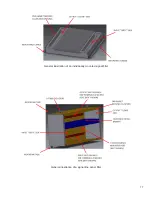

Inspection and Cleaning of Wiring Compartments

1.

Remove power from the filter(s).

2. Wait at least sixty (60) seconds, then remove the wiring compartment covers.

3.

Short the filter terminals to the filter case using a conductive shorting stick (not included) to ensure that the filter

capacitors are fully discharged.

4.

Inspect the filter terminals and insulators for contamination and/or damage.

5.

If the terminals or insulators are cracked or damaged replacement in the field is not possible.

Call ETS-Lindgren for instructions.

6. Clean the terminals and insulators as necessary, and remove any loose debris from the wiring compartments.

7. Re-install the wiring compartment covers. Ensure even compression of the RF gasket around the RF tight

wiring compartment. Begin by torquing all of the cover screws to 1 N-m, starting in the center of each flange

and working out towards the corners. Then, using the same pattern torque all screws to 5 N-m.

8.

Re-apply power to the filter(s).

Summary of Contents for EMI

Page 2: ......

Page 4: ...4 ...

Page 15: ...15 ILLUSTRATIONS Filter Penetration Filter penetrations should be installed as shown ...

Page 18: ...18 Individually mounted 4 line signal filter Individually mounted 2 line signal filter ...

Page 19: ...19 Panel signal filter Individually mounted 10 to 12 line signal filter ...

Page 20: ...20 ...

Page 22: ......