Description of the configuration wizard

5

2

Description of the configuration wizard

Configuration with the wizard

Configuration with the wizard takes place in several

steps. These are described below:

1) Add the function blocks required for the installed

heating system components. Choose your settings

and options individually in each function block.

2) When you have added all the necessary function

blocks, set the individual connections between

"producers" and "consumers".

"Producers" are components that provide heat or

fuel. "Consumers" consume this heat or fuel.

3) Next, the terminal assignments of each function

block is displayed on the corresponding circuit

board. In this step, the heating system

components are electrically connected. You may

also adjust the terminal assignments during this

step.

4) Finally, the configuration is installed, and the

software rebooted.

After this, you can make customer-specific

adjustments to the heating system, such as: buffer

charging times, room temperatures for the heating

circuit, hot water temperatures, etc.

When you have completed these customer adap-

tations, save this configuration. It is saved in the

ETAtouch control system. You can additionally save it

on a USB stick.

The description below explains the general way

in which the configuration wizard works. Your

heating system's individual configuration depends on

the installed components, and can vary.

Starting the configuration assistant

In the system configuration

, increase the authori-

sation to [Service] and open the system configuration

menu with the [Systems configuration] button.

Fig. 2-1: System configuration menu

Start the configuration assistant with the

[Starting

the assistant] button.

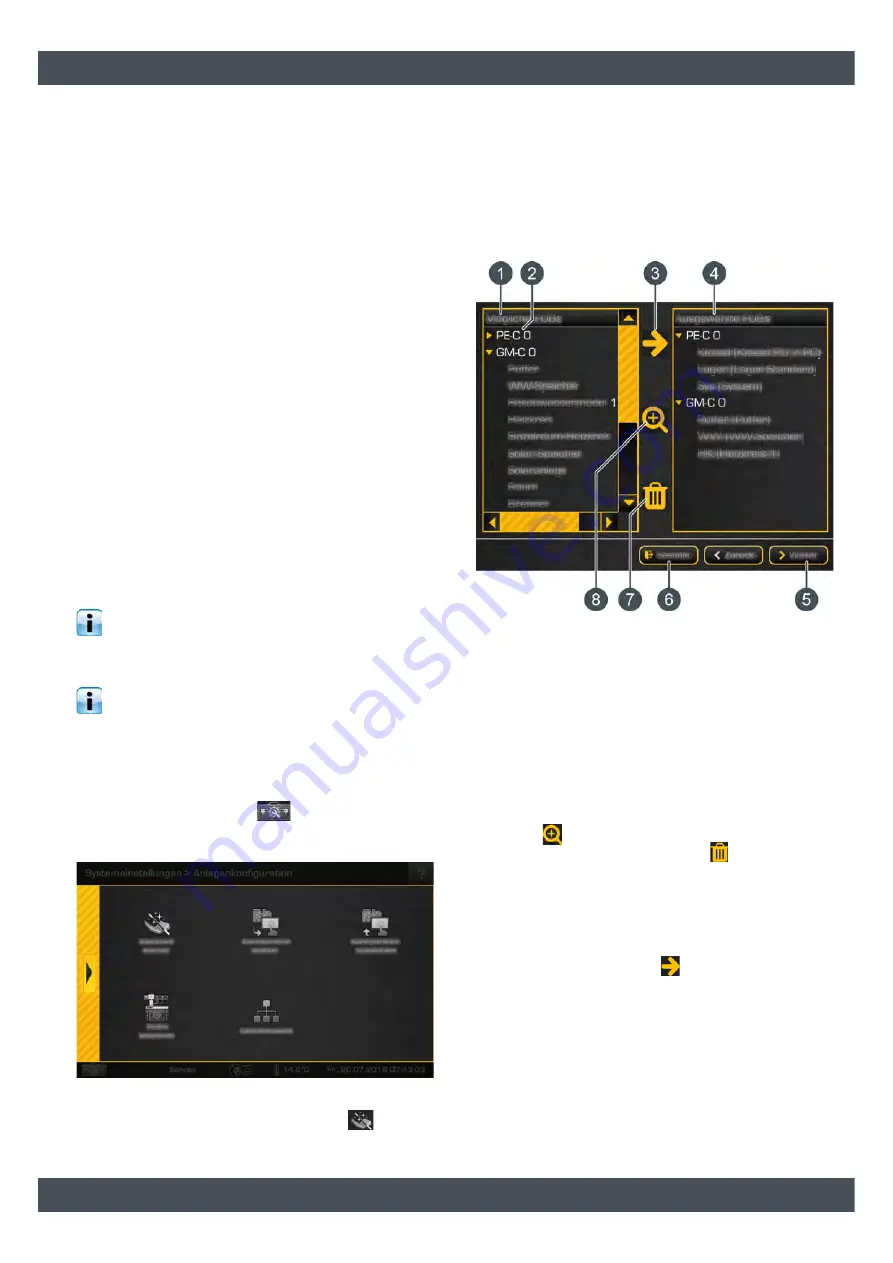

Function block overview

The [Possible function blocks] column shows the

function blocks available for selection, and the

[Selected function blocks] column shows the function

blocks that have already been added.

Fig. 2-2: Function block overview

1

Function blocks available for selection

2

Type and node number of circuit board

3

Add a function block

4

Function blocks already added

5

Next step of configuration

6

End configuration

7

Delete an added function block

8

Show the options of an added function block

Press the

button to see the options and settings for

an added function block. With the

button function

blocks that have already been added can be deleted.

Adding another function block is quick and uncompli-

cated. In this example, the [Heating circuit] function

block is used to explain the process. Select the

function block from the [Possible function blocks]

column, and then press the

button.