ESAB ET 186i AC/DC

BASIC WELDING GUIDE 4-12 Manual 0-5425

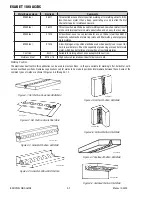

Tungsten Electrode Types

Electrode Type

(Ground Finish)

Welding Application

Features

Color Code

Thoriated 2%

DC welding of mild

steel, stainless steel

and copper

Excellent arc starting,

Long life, High current

carrying capacity

Red

Zirconated 1%

High quality AC

welding of aluminium,

magnesium and their

alloys.

Self cleaning, Long

life, Maintains balled

end, High current

carrying capacity.

White

Ceriated 2%

AC & DC welding

of mild steel,

stainless steel,

copper, aluminium,

magnesium and their

alloys

Longer life, More

stable arc, Easier

starting, Wider current

range, Narrower more

concentrated arc.

Grey

Table 4-5 Tungsten Electrode Types

Base

Metal

Thickness

AC Current for

Aluminium

Tungsten

Electrode

Diameter

Filler Rod Diameter

(if required)

Argon Gas

Flow Rate

JOINT

TYPE

1/16"

1.6mm

60-80

70-90

1/16"

1.6mm

1/16"

1.6mm

15 CFM

7 LPM

Butt/Corner

Lap/Fillet

1/8"

3.2mm

125-145

140-160

3/32"

2.4mm

1/16"-3/32"

1.6mm - 2.4mm

17 CFM

8 LPM

Butt/Corner

Lap/Fillet

Table 4-6 Aluminium Welding Material

Base Metal

Thickness

DC Current

for Mild

Steel

DC Current

for Stainless

Steel

Tungsten

Electrode

Diameter

Filler Rod

Diameter (if

required)

Argon Gas Flow

Rate

Joint Type

0.040"

1.0mm

35-45

40-50

20-30

25-35

0.040"

1.0mm

1/16"

1.6mm

10 CFH(5 LPM)

Butt/Corner

Lap/Fillet

0.045"

1.2mm

45-55

50-60

30-45

35-50

0.040"

1.0mm

1/16"

1.6mm

13 CFH(6 LPM)

Butt/Corner

Lap/Fillet

1/16"

1.6mm

60-70

70-90

40-60

50-70

1/16"

1.6mm

1/16"

1.6mm

15 CFH(7 LPM)

Butt/Corner

Lap/Fillet

1/8"

3.2mm

80-100

90-115

65-85

90-110

1/16"

1.6mm

3/32"

2.4mm

15 CFH(7 LPM)

Butt/Corner

Lap/Fillet

3/16"

4.8mm

115-135

140-165

100-125

125-150

3/32"

2.4mm

1/8"

3.2mm

21 CFH(10 LPM) Butt/Corner

Lap/Fillet

1/4"

6.4mm

160-175

170-200

135-160

160-180

1/8"

3.2mm

5/32"

4.0mm

21 CFH(10 LPM) Butt/Corner

Lap/Fillet

Table 4-7: Welding Rate

TIG Welding is generally regarded as a specialised process that requires operator competency. While many of the principles out-

lined in the previous Arc Welding section are applicable a comprehensive outline of the TIG Welding process is outside the scope of

this Operating Manual. For further information please refer to www.victortechnologies.com or contact Tweco.