11

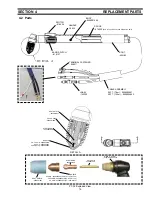

2.3 STEEL HEAT SHIELD GUARDS

(Refer to Figure 2-2)

ADJUST GUIDE BY TURNING IN A

CLOCKWISE DIRECTION ONLY. THIS

WILL PREVENT ACCIDENTAL LOOS-

ENING OF SHIELD.

STEEL GUARD

STAND OFF GUIDE

P/N 0558002393

IF GUIDE IS TOO

TIGHT ON SHIELD,

OPEN SLOT WITH

SCREWDRIVER.

IF TOO LOOSE, CLOSE

SLOT WITH VISE OR

LARGE PLIERS.

3/16" (4.6 mm)

TORCH-TO-WORK

GUIDE AGAINST

STRAIGHT EDGE

OR FREE-HAND

CUT

Figure 2-2. Installation and Operation of Steel Heat Shield Guards

SECTION 2

ASSEMBLY AND OPERATION

Drag cutting, even with lower current levels may significantly

reduce the life of torch consumables. Attempting to Drag Cut

with higher currents (70 amps) may cause immediate cata-

strophic consumable damage.

NOTICE

Drag Cutting with the PT-32 Torch

If drag cutting is desired, attach ESAB's standoff guide

(P/N 0558002393). For thin material, under 3/8", re-

move 50-70 amp or 90 amp nozzle from torch head,

insert ESAB's 40 amp nozzle (P/N 0558002908). Lower

current level to 40 amps or lower.