10

2.1 GENERAL

Make sure power switch on console is in the

"OFF" position and primary input power is

deenergized.

2.2 ASSEMBLY

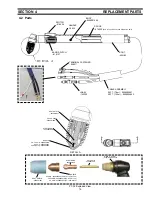

Install PT-32 front end parts as shown in Figure 2-1.

The torch head contains a gas flow check valve and a nozzle back pressure tap that act in conjunction with

circuitry within the power source. This system prevents the torch from being energized with high voltage if

the torch switch is accidentally closed when the shield is removed. ALWAYS REPLACE TORCH WITH THE

PROPER TORCH MANUFACTURED BY ESAB SINCE IT ALONE CONTAINS ESAB'S PATENTED SAFETY IN-

TERLOCK.

!

WARNING

SECTION 2

ASSEMBLY AND OPERATION

*

The valve pin is a crucial member of the sys-

tem. Its function is to open the gas flow check

valve that is permanently assembled within

the torch head. If the pin is not correctly placed

in the electrode, the valve will not open and

the system will not function. The valve pin also

improves electrode cooling by increasing the

velocity of air over the inner surface of the elec-

trode.

VALVE PIN

ELECTRODE

NOZZLE

SHIELD

*

PLACE NOZZLE INTO HEAT SHIELD

AND THREAD THIS ASSEMBLY TO THE

TORCH BODY AND HAND TIGHTEN.

2

3

IMPORTANT!

MAKE SHIELD VERY TIGHT!

PLACE THE VALVE PIN INTO THE

ELECTRODE AND SCREW THE

ELECTRODE INTO THE TORCH

HEAD AND TIGHTEN SECURELY

WITH WRENCH #19120.

1

Figure 2-1. Assembly of PT-32 Torch Front End Parts