© ESAB AB 1999

- 6 -

bg03d1ea

Welding hose

A9-250

A9-400

Permissible load at 60% duty cycle

Length: 5 m, 10 m, 16 m

250 A

400 A

Electrode diameter

0.8-1.2 mm

0.8-1.6 mm

Working pressure

490 kPa (5 kp/cm

2

)

490 kPa (5 kp/cm

2

)

Max. testing pressure

735 kPa (5 kp/cm

2

)

735 kPa (5 kp/cm

2

)

NB.

Make sure the gun motor has the proper working pressure, 490 kPa (5 kp/cm

2

).

If the pressure is lower the motor will not get the right speed, resulting in too low wire

feed speed and welding current. If the pressure is higher the welding hose will be

exposed to harmful dynamic pressure.

4

INSTALLATION

The installation must be carried out by a professional.

4.1

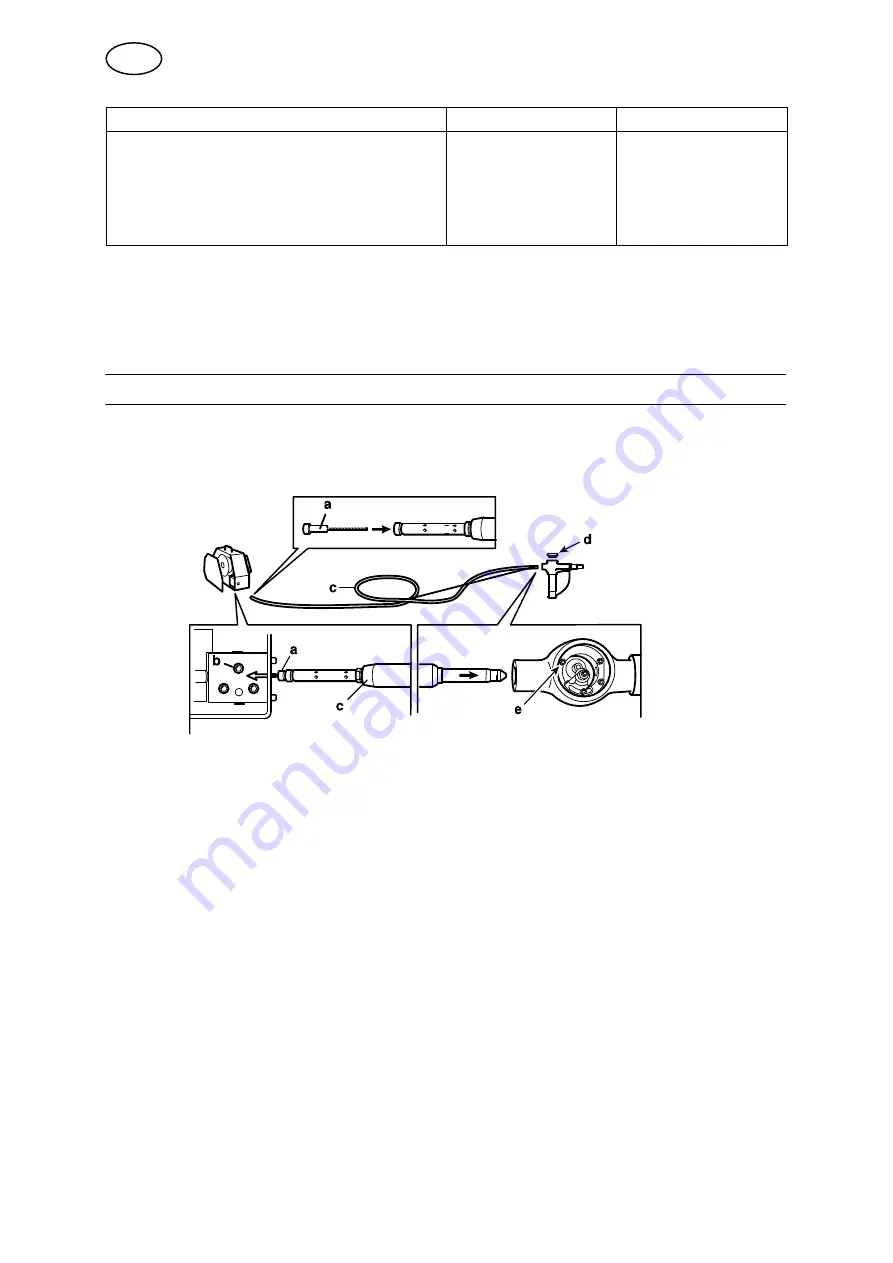

Connecting the welding hose

S

Press the inlet nozzle (

a

), - selected according to the diameter of the wire - into

the welding hose.

S

Open the wire feed unit on the bobbin side.

S

Undo the locking screw (

b

) on the connecting plate.

S

Connect the welding hose (

c

) to the wire feed unit and tighten the locking screw

on the connecting plate.

S

Remove the plastic cover (

d

) from the gun housing.

S

Undo the locking screw (

e

) and press the other end of the hose into the gun.

S

Tighten the locking screw and fit the plastic cover.

GB