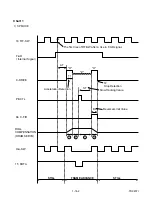

2-3-2

TD951MA

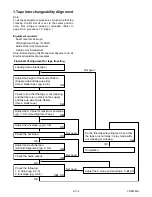

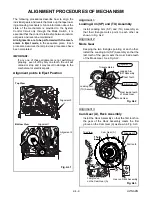

Adjust the X Value for maximum envelope.

(pg. 2-3-3) (Use Alignment Tape.)

Check to see that the tape is not creasing

and that there is no slack on the supply

and take-up side Guide Rollers.

(Use a blank tape.)

Adjust the height of the Guide Rollers

(Supply side and take-up side).

(Use a blank tape.) (pg. 2-3-3)

Loading (Use a blank tape.)

Adjust the envelope. (pg. 2-3-4)

Check the envelope.

Adjust the Audio Section.

(Azimuth Alignment) (pg. 2-3-4)

Check the audio output.

Check the following:

1. X Value (pg. 2-3-3)

2. Envelope (pg. 2-3-4)

Adjust the X value and envelope.

Not good

Do the final tape-traveling test to see that

the tape runs normally in play mode with-

out creasing or slacking.

Completion

Not good

OK

OK

OK

Not good

Not good

OK

Flowchart of Alignment for tape traveling

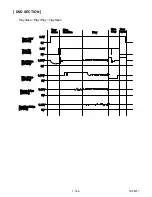

1-A

1-A

1-B

1-C

1-C

1-D

1-D

1-B, 1-C

1-B, 1-C

1-A

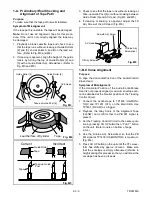

1.Tape Interchangeability Alignment

Note:

To do these alignment procedures, make sure that the

Tracking Control Circuit is set to the center position

every time a tape is loaded or unloaded. (Refer to

page 2-3-4, procedure 1-C, step 2.)

Equipment required:

Dual Trace Oscilloscope

VHS Alignment Tape (FL8NW)

Guide Roller Adj. Screwdriver

X-Value Adj. Screwdriver

Note: Before starting this Mechanical Alignment, do all

Electrical Adjustment procedures.

Summary of Contents for EC720E

Page 2: ...EC720E T1008UJ 2004 06 22 ...

Page 22: ...1 7 4 TD900DC S 4 S 4 S 4 S 4 4 CRT Anode Cap CRT CBA Fig 3 ...

Page 93: ...2 4 8 TD951DA Fig DM16 41 42 43 L 13 44 45 P 9 Slide Fig DM17 ...

Page 97: ...3 1 3 TD900PEX S4 S1 X1 TAPE X5 X4 X2 X3 S3 S6 S7 S2 PACKING TAPE Packing ...

Page 119: ...Printed in Japan 2003 08 25 HO 6720FDD TD900UA ...