11

ROUTINE

MAINTENANCE

Lower the attachment to rest on the parking stands, shut down the engine, relieve the

hydraulic pressure to the attachment, set the park brake, and wait for all motion to stop before leaving

the operator’s seat to perform service of any kind.

It is the operator’s responsibility to make daily inspections of the loader and attachment for damage, loose bolts,

fluid leaks, or anything else that could cause a potential service or safety problem. Preventive maintenance is

the easiest and least expensive type of maintenance.

IMPORTANT:

Bolts and set screws can loosen after initial usage. After the first hour of operation check all bolts

and set screws.

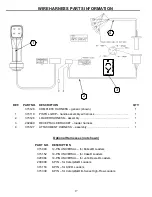

[A]

[B]

Use No. 2 lithium base gun grease when lubricating

all attachment grease fittings.

Grease the pivot bushing zerk

[A]

every

8 hours

of

operation.

Grease the bearing mount zerk

[B]

every

80 hours

of

operation.

IMPORTANT:

Do not over-grease bearing. Only add

two pumps

of grease every greasing interval.

8

No. 2 Lithium

base gun grease

Clean engine oil

LUBRICATION

80