Figure 12. Fluid Levels

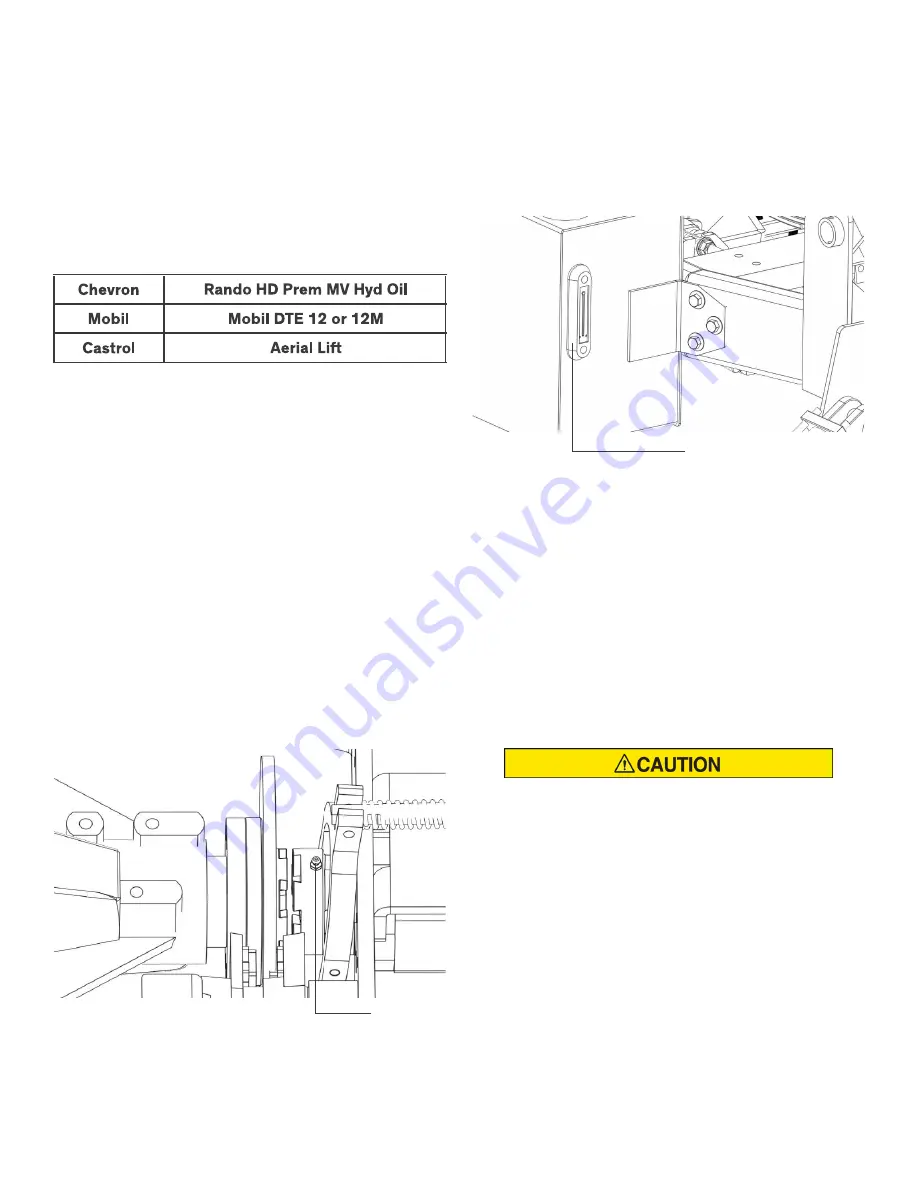

Figure 13. Grease Fittings Locations

13

• Check Hydraulic Fluid Level - With the Equipter on level ground, the dump bed down and retracted,

the outriggers raised, and the steering wheels down. The hydraulic oil level should be visible in the

sight gauge in between the top and bottom of the temperature gauge (normal reading should be

between 1/4 and 1/2 on the gauge). If necessary to refill, use only approved hydraulic oil.

New Heights, LLC recommends changing the hydraulic oil filter every 6 months and the hydraulic oil every

3 years.

The following are approved oil sources:

NOTE: Maximum recommended hydraulic oil

operating temperature is 160° F (71° C).

Every 40 hours of operation or weekly the following should be checked:

• Check Tire Inflation Pressure - Refer to “Tire and Loading Information” placard located on the

hitch.

• Check that all wheel lugs nuts are tight. If not, they must be torqued to the proper specification.

• Lubricate rollback slide rails - Apply grease to frame rails where dump box slides. Use multi-

purpose grease (NLGI #2).

• Check rear axle oil level.

• Lubricate all Grease Fittings - Grease fittings are located at most pivot areas.

Be sure to lubricate like items on the

opposite sides of the Equipter. Worn grease

fittings that will not hold the grease gun, and

fittings with a stuck ball, must be replaced.

Grease Zerk

Summary of Contents for RB4000

Page 2: ......

Page 6: ...iv RIGHT Hydraulic Tank Side REAR Tail Gate LEFT Operator Side FRONT Hitch ...

Page 9: ...3 Figure 2 Decals ...

Page 45: ......

Page 46: ...855 378 4783 www equipter com 49 Eagle Drive Leola PA 17540 ...