33

Chapter 2 Setup

2

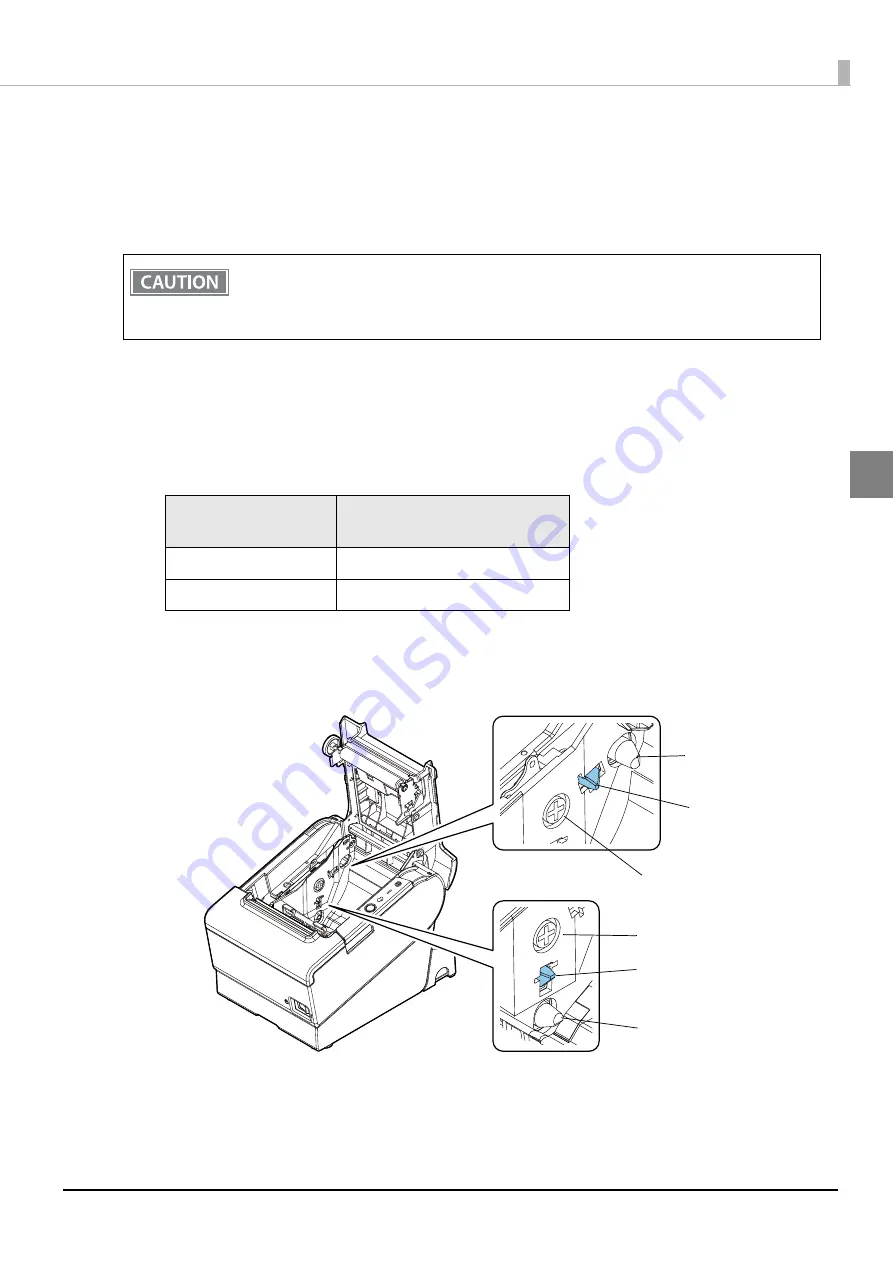

Adjusting the Paper Roll Near-End Sensor

Below are two situations where a roll paper NE sensor adjustment is required.

To adjust the detection position to suit the diameter of the roll paper core used.

To adjust the detection position of remaining amount of paper.

Follow the steps below to adjust the roll paper near-end detector.

1

Open the roll paper cover, and remove the roll paper.

2

Loosen the adjustment screw fastening the sensor, and align the upper edge of the

positioning plate with the adjustment position.

3

Tighten the adjustment screw.

4

After adjustment, make sure that the detection lever operates smoothly.

Since roll paper cores vary slightly in shape, depending on paper roll design and manufacturing

tolerances, it is impossible to detect the remaining paper exactly.

Use roll paper with a core inner diameter of 12 mm {0.47"} and outer diameter of 18 mm {0.71"} so

that the NE sensor can detect the remaining paper as accurately as possible.

Adjustment position

Remaining amount of paper

(outer diameter: mm)

Upper

Approx. 27 {1.06"}

Lower (Default setting)

Approx. 23 {0.97"}

Detection lever

Positioning

plate

Adjustment screw

Adjustment screw

Positioning

plate

Detection lever

For wall-hanging

For horizontal installation

Summary of Contents for TM-T88VI-iHUB

Page 12: ...12 ...

Page 54: ...54 ...

Page 113: ...113 Chapter 5 Handling 5 5 Tear off the paper ...

Page 115: ...115 Chapter 5 Handling 5 3 Remove the jammed paper 4 Close the covers ...

Page 122: ...122 ...

Page 133: ...133 Appendix Units mm ...

Page 136: ...136 Italian Spanish English UK Keyboard type Key layout ...

Page 156: ...156 ...