EPSON Stylus Pro 7400/7800/9400/9800

Revision B

Product Description

Control Panel

59

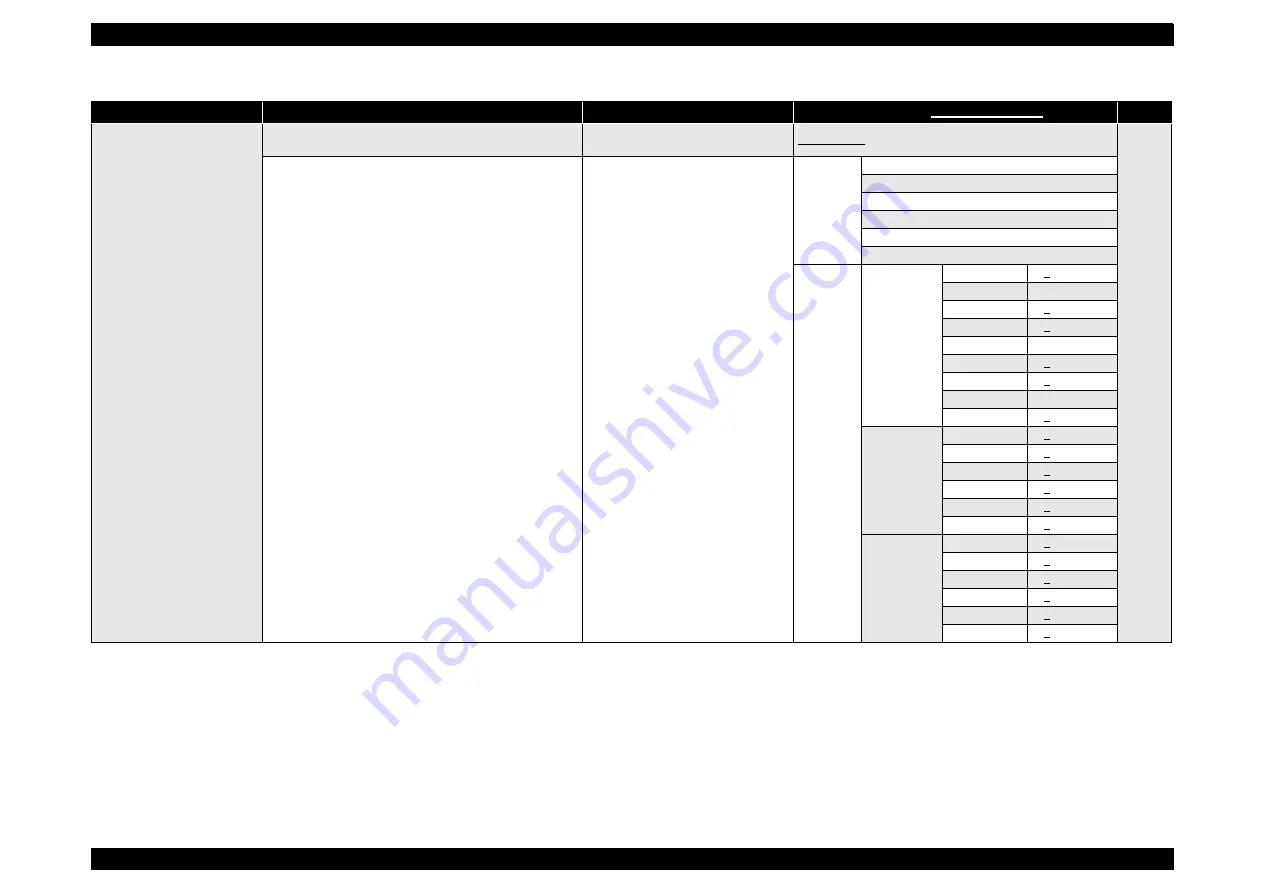

Gap Adjustment Menu

(GAP ADJUSTMENT)

Paper Thickness (in 0.1mm units) *1

PAPER

THICKNESS

STANDARD

, 0.1mm~1.5mm

Select and Print Adjustment Pattern

ALIGNMENT

AUTO

UNI-D

BI-D 2 COLOR

BI-D ALL

BI-D #1

BI-D #2

BI-D #3

MANUAL

UNI-D

#1 C

1~

5

~9

:

:

#1 LLK

1~

5

~9

#2 C

1~

5

~9

:

:

#2 LLK

1~

5

~9

#3 C

1~

5

~9

:

:

#3 LLK

1~

5

~9

BI-D 2

COLOR

#1 LC

1~

5

~9

#1 LM

1~

5

~9

#2 LC

1~

5

~9

#2 LM

1~

5

~9

#3 LC

1~

5

~9

#3 LM

1~

5

~9

BI-D 2

COLOR

#1 C

1~

5

~9

#1 M

1~

5

~9

#2 C

1~

5

~9

#2 M

1~

5

~9

#3 C

1~

5

~9

#3 M

1~

5

~9

Continued to next page

Table 1-37. Panel Setting Mode Items List (continued)

Top menu (Panel display)

Item menu

Panel display

Set value (Underline: Default)

Ref.

Summary of Contents for Stylus Pro 7400

Page 1: ...EPSONStylusPro7400 7800 9400 9800 Large Format Color Inkjet Printer SERVICE MANUAL SEIJ05002 ...

Page 10: ...C H A P T E R 1 PRODUCTDESCRIPTION ...

Page 147: ...C H A P T E R 2 OPERATINGPRINCIPLES ...

Page 170: ...C H A P T E R 3 TROUBLESHOOTING ...

Page 207: ...C H A P T E R 4 DISASSEMBLY ASSEMBLY ...

Page 292: ...C H A P T E R 5 ADJUSTMENT ...

Page 373: ...C H A P T E R 6 MAINTENANCE ...

Page 380: ...C H A P T E R 7 APPENDIX ...

Page 385: ...Model PX 7500 7500S 9500 9500S Board C594 Main Sheet 1 of 4 Revison G ...

Page 386: ...Model PX 7500 7500S 9500 9500S Board C594 Main Sheet 2 of 4 Revison F ...

Page 387: ...Model PX 7500 7500S 9500 9500S Board C594 Main Sheet 3 of 4 Revison F ...

Page 388: ...Model PX 7500 7500S 9500 9500S Board C594 Main Sheet 4 of 4 Revison E ...

Page 389: ...Model PX 7500 7500S 9500 9500S Board C594 SUB Sheet 1 Revison C ...

Page 390: ...Model PX 7500 7500S 9500 9500S Board C594 SUB B Sheet 1 Revison E ...

Page 391: ...Model PX 7500 7500S 9500 9500S Board C594 SUB C Sheet 1 Revison D ...

Page 392: ...Model PX 7500 7500S 9500 9500S Board C594 PNL Sheet 1 Revison D ...

Page 396: ...PX 7500 7500S E PS ON S TYLUS PR O 7400 7800 No 03 R ev 01 C594 E LE C 011 202 201 200 ...

Page 397: ...PX 7500 7500S E PS ON S TYLUS PR O 7400 7800 No 04 R ev 01 C594 E LE C 021 203 204 ...

Page 398: ...PX 7500 7500S E PS ON S TYLUS PR O 7400 7800 No 05 R ev 01 C594 POWE 011 300 301 302 ...

Page 403: ...PX 7500 7500S E PS ON S TYLUS PR O 7400 7800 No 10 R ev 01 C594 ME CH 051 700 701 X15 700 ...

Page 410: ...R ev 01 C595 E LE C 011 200 201 202 PX 9500 9500S E PS ON S TYLUS PR O 9400 9800 No 03 ...

Page 411: ...PX 9500 9500S E PS ON S TYLUS PR O 9400 9800 No 04 R ev 01 C595 E LE C 021 204 203 ...

Page 412: ...PX 9500 9500S E PS ON S TYLUS PR O 9400 9800 No 05 R ev 01 C595 POWE 011 300 302 301 ...

Page 417: ...PX 9500 9500S E PS ON S TYLUS PR O 9400 9800 No 10 R ev 01 C594 ME CH 051 701 X15 700 700 ...