M200 / M205 / M100 / M105 Series

Revision A

Adjustment

Required Adjustments

66

Confidential

Part Name

CR Unit

Remove

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

Replace

---

---

---

---

---

O

O

O

O

---

O

O

---

---

---

---

CR Timing Belt

Remove

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

Replace

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

Frame Base Assy

Replace

---

---

---

---

---

O

O

---

O

O

O

O

---

---

---

---

PF Roller Unit

Remove

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

Replace

---

---

---

---

---

---

O

---

---

O

O

---

O

---

---

---

PF Motor Assy

Remove

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

Replace

---

---

---

---

---

---

---

---

---

O

---

---

---

---

O

---

Frame Base

Replace

---

---

---

---

---

O

O

---

O

---

---

---

---

---

---

---

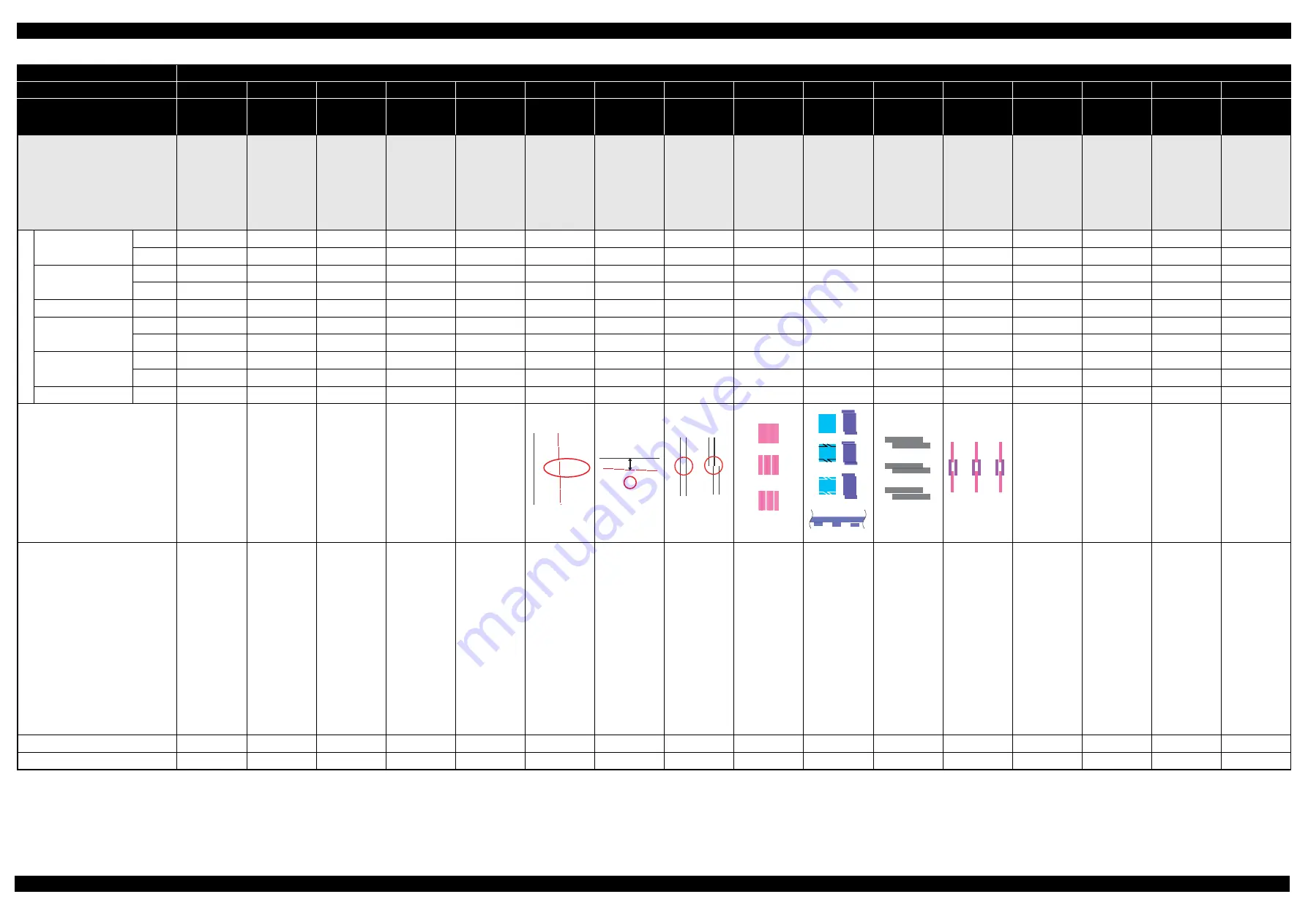

Table 3-2. Required Adjustment List

Adjustment Type

Adjustment using the Adjustment Program

Priority

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Adjustment Item

EEPROM

data copy

Initialize Setting

Head ID input

Ink charge

Maintenance

counter

First dot position

adjustment

TOP margin

adjustment

Head angular

adjustment

Bi-D adjustment

PF/EJ

adjustment

PF band

adjustment

Paper skew

adjustment

PF deterioration

offset

CR motor heat

protection

control

PF motor heat

protection

control

Scanner motor

heat protection

control

Purpose

To copy adjustment

values or the like

stored on the old

Main Board to the

new board when

the Main Board

needs to be

replaced.

To write sale-

destination-specific

settings and the

serial number into

the Main Board

after replacing it.

And also to set the

MAC address as

necessary.

To correct

characteristic

variation of the

replaced Printhead

by entering its

Printhead ID

(Head ID).

To fill ink inside

the new Printhead

to make it ready

for print after

replacing the

Printhead.

To reset the waste

ink counter after

replacing the

Waste Ink Pad

Assy.

To correct the

print start position

in the CR Unit

moving direction

through software

control.

This corrects top

margin of printout.

To correct tilt of

the Printhead

caused at the

installation

through software

control.

To correct print

start timing in

bidirectional

printing through

software control.

To correct

variations in paper

feed accuracy to

achieve higher

print quality.

To correct

variations in paper

feed accuracy to

achieve higher

print quality in

band printing.

To align print start

position at 0-digit

side with that at

80-digit side in

bidirectional band

printing, timing of

firing ink droplet

is adjusted

through software

control.

To reset the

counter according

to the replaced

parts.

To measure and

correct the

electrical variation

of the motor and

the power supply

board.

To measure and

correct the

electrical variation

of the motor and

the power supply

board.

To measure and

correct the

electrical variation

of the motor.

Printout pattern

---

---

---

---

---

---

---

---

---

How to judge

---

---

---

---

---

Examine the

misaligned lines

printed on the left

side of the paper,

and enter the

number beside the

line that is exactly

5 mm away from

the paper edge.

Examine the

misaligned lines

printed on top of

the paper, and

enter the number

beside the line that

is exactly 5 mm

away from the

paper edge.

Enter the values of

the most straight

lines.

Examine the

printout patterns

for each of the

four modes, and

enter the value for

the pattern with no

gap and overlap

for each mode.

Normal area

pattern

Examine the

printout patterns

and enter the

value for the

pattern with

fewest lines.

Bottom area

pattern

Examine the

printout patterns

and enter the

value for the

pattern with no

overlap and gap

between the two

rectangles.

Examine the

printout patterns

and enter the value

for the pattern

with no overlap

and gap between

the two rectangles.

Examine the

printout pattern

and enter the

number of the one

with the least gap

and overlap

between the two

different colored

lines.

---

See

" 3.2.2.1 CR

Motor Heat

Protection Control

/ PF Motor Heat

Protection Control

(p67)"

for the

details.

See

" 3.2.2.1 CR

Motor Heat

Protection Control

/ PF Motor Heat

Protection Control

(p67)"

for the

details.

See

" 3.2.3

Scanner Motor

Heat Protection

Control (p68)"

for

the details.

Adjustment program

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

Tool

---

---

---

---

---

Ruler

Ruler

---

---

---

---

---

---

---

---

---

Note "*1": Replacement of the Paper Guide Lower Porous Pad and Waste Ink Pad Assy is necessary.

-2

-1

0

1

2

-

2

-1 0 1 2

NG

OK

OK

NG

NG

OK

NG

NG

OK

NG

NG

OK

NG

NG

OK NG

NG

Summary of Contents for M200

Page 1: ...SERVICE MANUAL CONFIDENTIAL Color Inkjet Printer M200 M201 M205 M100 M101 M105 SEMF12 012 ...

Page 9: ...Confidential CHAPTER 1 TROUBLESHOOTING ...

Page 18: ...Confidential CHAPTER 2 DISASSEMBLY REASSEMBLY ...

Page 59: ...Confidential CHAPTER 3 ADJUSTMENT ...

Page 73: ...Confidential CHAPTER 4 MAINTENANCE ...