Installation Guide

87

f

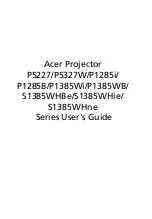

Touch the center of the dot with your finger

When the dot disappears and moves to the next position, remove your finger.

c

•

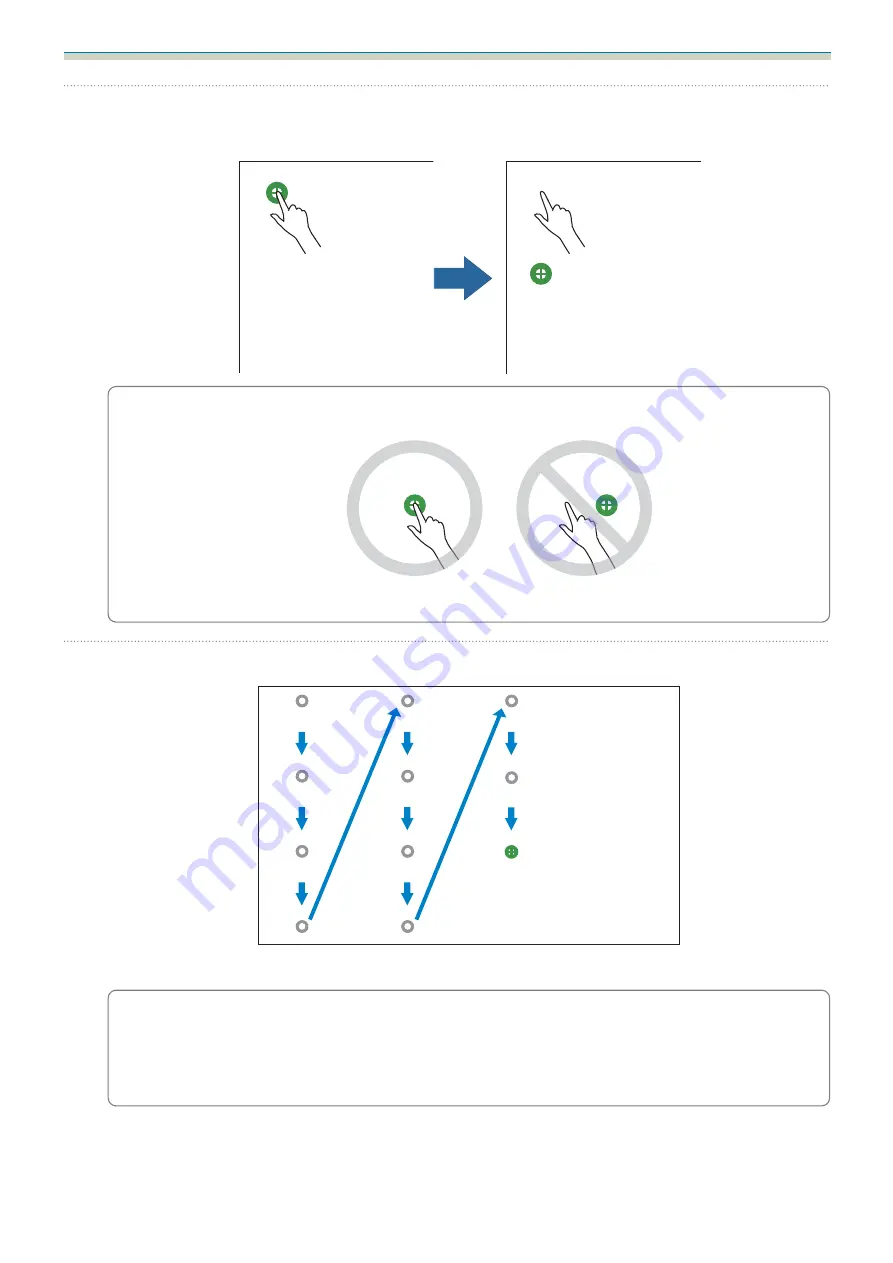

Make sure you touch the center of the dot. Otherwise, it may not be positioned correctly.

•

Do not touch with anything else except the tip of your finger.

g

Repeat step 6 until all of the dots disappear

When all of the dots disappear, touch calibration is complete.

c

•

If you touch the wrong position, press the [Esc] button on the remote control or control panel.

This returns you to the previous dot. You cannot go back by two dots.

•

To cancel touch calibration, hold down the [Esc] button for two seconds.

•

It may take several seconds after all of the dots have disappeared until touch calibration is

complete.