www.enware.com.au

Call 1300 369 273

9

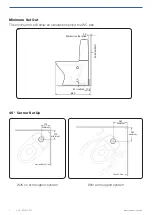

Fixing With Pan Screws:

Determine if using pan screws would be appropriate

according to the quality and strength of the floor material, and

the site risk assessment, taking into account the thickness

of floor surface and mortar bed, the distance to structural

concrete slab, and the impact to waterproofing membrane.

Ensure the pan screws can be fixed onto floor material with

adequate structural integrity and strength. If pan screws

are not long enough or they cannot be fixed onto floor

with adequate strength, use floor mounting bracket with

appropriate fixings. (Floor mounting bracket IFO98016 sold

separately.)

Installing the Pan:

1. Through the pan fixing holes, mark the floor then

pre-drill holes on the floor. The holes should be

drilled at a slight angle and approx. 50mm deep.

2. WC pan should be bedded with silicone sealant.

Ensure the floor surface and bottom surface of

pan are clean and dry, free of dust, moisture and

grease.

3. Apply silicone sealant to the entire bottom contact

surface of pan and around the perimeter to

achieve good adhesion and to create a strong

bonding between the pan and the floor.

4. Install pan into position.

5. Fix the pan in place with pan screws. Hand

tighten the screws, but do not over-tighten. (Over-

tightening screws will cause the ceramic to crack.)

6. Attach white screw caps (supplied) onto the heads

of fixing screws.

30 - 40

98

Base level

of pan

4

Pan Screw

50

60°-65°