ENVIRO-TEC

14

FORM ET115.24-NOM4 (819)

SECTION 1 - RECEIPT & INSTALLATION

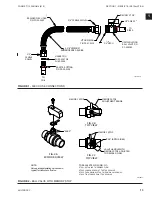

FLEX HOSE

All Vertical Hi-Rise and Tandem Master & Tandem

Slave units use Kevlar reinforced braided stainless

steel flexible hoses for all water piping between the

coil and the risers or field piping. This factory piping

includes two ball valves per coil, with memory stop.

These hoses are designed with swivel connections on

both ends, and require either a gasket or O-ring for

positive sealing. See

Figure 1 on page 13

for con-

nection details.

These hoses are designed to provide for riser move-

ment due to thermal expansion, and allow for quick,

easy coil removal through the use of the swivel con-

nections.

During transit, vibration may cause a connection to

loosen. Therefore, all threaded connections must be

checked during unit installation. Any fitting that is

loose must be tightened. The stationary side of any

swivel connection must be prevented from twisting

during tightening by the use of a “backup” wrench.

Pressure test all joints before applying water.

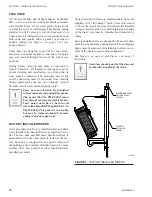

Some hose-to-coil joints are furnished

with a removable vulcanized fiber gasket.

This gasket (Part No. PH-05-0047) must

be replaced each time the joint is broken.

Later model units have a hose-to-coil

joint with a black EDPM gasket (Part No.

PH-05-0048). This gasket is re-useable,

but may be replaced should it become

damaged and no longer seal.

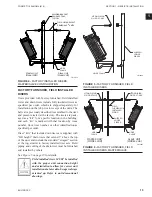

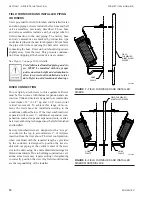

FACTORY INSTALLED RISERS

Units provided with factory installed water and drain

risers include fully insulated risers as specified per or-

der. The flex hose and ball valve described above is

assembled to the riser and pressure tested at the fac-

tory. Each unit is configured for a specific location in

the building, and is marked with that location by room

number, floor, riser number, or other identification as

specified per order.

Units provided with factory installed drain risers are

supplied with “full height” drain risers that extend

3” above the top of the unit, and include the standard

“swaged” section at the top. Field piping and venting

of the drain riser must be furnished and installed by

others.

Factory installed risers are strapped to the unit for ship-

ment to prevent damage during transit. These shipping

straps must be removed at installation to allow move-

ment of the risers to assure proper alignment.

See

Figure 3 on page 14

and

Figure 4 on page 15

for details.

At no time should a unit be lifted, moved,

or otherwise handled by the risers.

RISERS

INSTALLED

FACTORY

TYPICAL

REMOVE STRAP,

SHIPPING BRACKET,

FIGURE 3 -

FACTORY INSTALLED RISERS

LD13872

Summary of Contents for VHA

Page 10: ...ENVIRO TEC 10 FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 41: ...ENVIRO TEC 41 SECTION 2 START UP FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 54: ...ENVIRO TEC 54 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data 74 80083 ...

Page 78: ...ENVIRO TEC 78 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data NOTES ...