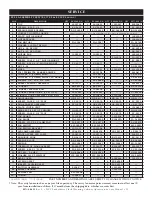

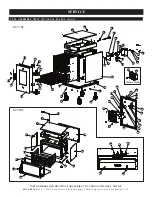

MN-28671

Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 7

The following refers to features that are available when the control is

powered on.

CONTROL PANEL KEYS

ON/OFF KEY

Press

the ON/OFF key to power on the control.

Press and hold

the ON/OFF key for 2 seconds to turn the control off. The status

indicator L.E.D. will illuminate in the power ON state.

Note:

The

IRR or INJ must be selected to turn on the heating circuit.

UP ARROW / DOWN ARROW KEYS

These keys are used to increase or decrease the temperature set-

point as desired. Continual pressure to a key will increase the

increments in which the values will change.

OVERTEMP ALARM KEY

Depressing this key displays the current over-temperature

trip-point. The alarm trip-point is always 6°C (10°F) above the

temperature setting. When the green OVERTEMP indicator is

blinking, the warmer has entered an over-temperature condition.

IRR KEY

The IRR key is used to select the IRRIGATION FLUIDS mode and

to display the IRR set-point temperature. The temperature range is

37° to 66°C (98° to 150°F). The green IRR indicator and the yellow

indicator below the IRR key illuminates when the IRR set-point

temperature is being displayed.

INJ KEY

The INJ key is used to select the INJECTION FLUIDS mode and

to display the INJ set-point temperature. The temperature range is

37° to 40°C (98° to 104°F). The green INJ indicator and the yellow

indicator below the INJ key illuminates when the INJ set-point

temperature is being displayed.

NOTE:

When the control is powered on, IRR or INJ must be selected

to turn on the heating circuit. To switch between the irrigation

and the injection mode, you must fi rst turn the control off and

back on. Be careful to cool the cavity down prior to switching

from a high temperature to a lower temperature or the control

will display an unwanted overtemp alarm.

L.E.D. DISPLAY STATUS INDICATORS

OVERTEMP

When the control senses a temperature 10°F (6°C) greater than

the set point, this indicator will illuminate. The audible alarm will

sound. The ON/OFF key indicator will fl ash. The green indicator of

the overtemp key will stop blinking once the warmer temperature

drops back to the set point temperature range. To silence the alarm

and extinguish the ERROR indicator after the temperature has

dropped into the selected temperature range, use the ON/OFF key

to reset the control. Inspection of the product in the cavity may

be necessary.

ERROR

This illuminates when an over-temperature condition is detected.

The ERROR indicator will remain illuminated, even after the

over-temperature condition is cleared, until the warmer is turned

off. This will alert the operator that the control has indicated an

OVERTEMP and the product in the cavity should be inspected.

LOCK

Illuminates when the lock feature is engaged.

POWER FAIL DETECT

If the power were to fail for any reason while control is powered

on, the warmer will retain in memory its current operating state.

When the power is restored, the control will alarm once and resume

operating in its previously set mode, but will alert the operator that

such an event has occurred: The ON/OFF status indicator will fl ash.

Press the ON/OFF key once to acknowledge that the power has been

restored. The ON/OFF status indicator will stop fl ashing. When

pushing the ON/OFF key, the display will indicate the time period

of the outage in hours and minutes (HH:MM), then return to the

normal display and previously set mode. Inspection of the product

in the cavity may be necessary.

FAHRENHEIT OR CELSIUS SELECTION

While the controller is in the OFF mode, press and hold the UP

ARROW key for 5 seconds to view the current setting. Press again

to switch between °F (Fahrenheit) or °C (Celsius).

CAVITY TEMPERATURE DISPLAY

To reference the cavity air temperature, push and hold the

OVERTEMP and UP ARROW keys. While holding both keys, the

value in the display refers to the temperature at the cavity sensor.

AUDIBLE ALARM SELECTION

While the controller is in the off mode, press and hold the DOWN

arrow key for 5 seconds. Press again to switch between audible

alarm ON (

Ι

) and OFF (

O

) mode.

CONTROL LOCK PROGRAMMING

The warmer control can be locked so that no changes can be made

to the temperature set-point or the mode selection. Press and hold

the ON/OFF key and the UP arrow key at the same time. The LOCK

indicator will illuminate. Attempts to operate the ON/OFF key, or

to change the temperature set-point will be unsuccessful. To unlock

the control, press and hold the ON/OFF key and the DOWN arrow

button at the same time. The control will unlock, and the LOCK

indicator will go out.

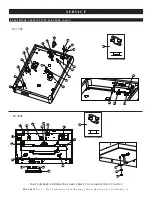

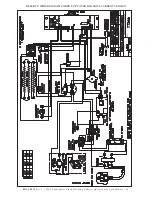

THERMOSTAT CONTROL AND L.E.D. DISPLAY

ON

/

OFF

KEY

STATUS

INDICATOR

L

.

E

.

D

.

STATUS

INDICATOR

L

.

E

.

D

.

IRRIGATION

MODE

KEY

UP

ARROW

DOWN

ARROW

OVERTEMP

ALARM

KEY

INJECTABLES

MODE

KEY

MAIN

DISPLAY

SET

-

POINT

TEMPERATURE

LOCK

OVERTEMP

ERROR

F L U I D C O N T R O L F E A T U R E S