Program setpoint 1 value, LED 1 activated.

The initially programmed value appears on the display with the first digit flashing.

Press repeatedly the

key to increment the active digit from 0 to 9 until it takes

the desired value and press

to advance to the next digit to be modified. Repeat

these operations to complete the desired setpoint value with sign.

Press

ENTER

to validate the entry and pass to the programming of setpoint 2.

[25.2] Setpoint 1

UP

SHIFT

DATA

ENTER

1

2

Program setpoint 2 value, LED 2 activated.

Program the setpoint 2 value with sign by means of the

(change value) and

(change digit) procedure as described in previous phase.

Press

ENTER

to store programmed data in the memory and exit from the

programming mode.

[25.3] Setpoint 2

UP

SHIFT

DATA

ENTER

1

2

To program the setpoint values, press

ENTER

to acceed the programming mode

(indication Pro, figure 25.1) and press

to make the display show the previously

programmed value of setpoint 1.

NOTE: The setpoint values should be programmed within the selected measurement

range.

[25.1] Setpoints Programming

UP

SHIFT

DATA

ENTER

1

2

7

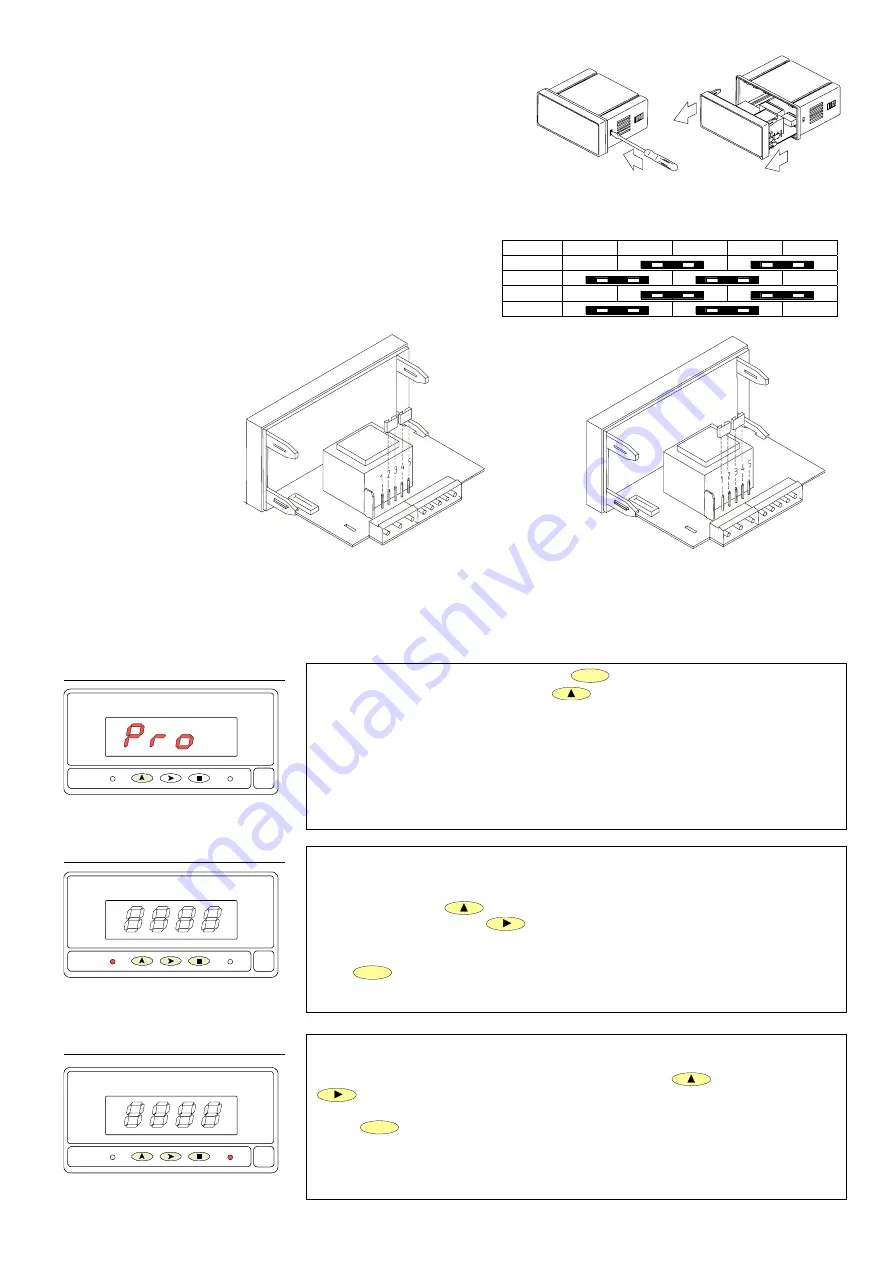

Fig. 9.1. Disassembly.

2.1 – Power supply and connectors

To change the meter’s physical configuration remove the case as

shown in figure 9.1.

115/230 V AC: The instruments with 115/230 V AC power are

set up at fabrication for 230 V AC (USA market 115 V AC), see

figure 9.2. To change power supply configuration to 115 V AC,

make the jumpers indicated in figure 9.3 and table 1. The wiring

label should be modified to match the new configuration.

24/48 V AC: The instruments with 24/48 V AC power are set up

at fabrication for 24 V AC, see figure 9.2. To change power

supply configuration to 48 V AC, make the jumpers indicated in

figure 9.3 and table 1. The wiring label should be modified to

match the new configuration.

12, 24 or 48V DC:

Instruments for DC

power are set up for

the supply voltage

specified in the wiring

label (12V, 24V or 48V

according to the order

reference).

Tabla 1. Jumper settings.

Pin 1 2 3 4 5

230V AC

-

115V AC

-

48V AC

-

24V AC

-

Fig. 9.3. Jumper settings for 115 V or 24 V AC

Fig. 9.2. Jumper settings for 230 V or 48 V AC

23