06

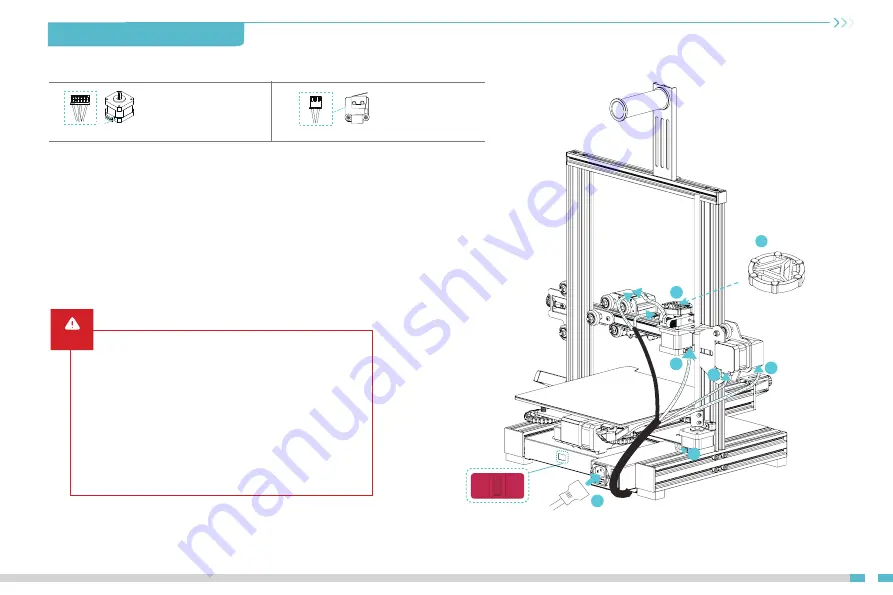

4.4 Cable Connection

X, E, Z-axis motor port

6pin (4 wires)

3pin (2 wires)

X-axis limit switch

A.

Put the indication knob directly onto the motor shaft;

B1.

Follow the yellow label on the 6pin (4 wires) port to connect the X-axis stepper motor;

B2.

Follow the yellow label on the 6pin (4 wires) port to connect the E-axis stepper motor;

B3.

Follow the yellow label on the 6pin (4 wires) port to connect the Z-axis stepper motor;

C.

Follow the yellow label on the 3pin (2 wires) port to connect the X axis limit switch;

D.

Plug in the power cord and toggle the switch to turn on the power.

Caution

●

Before powering on, be sure to select the correct

voltage mode according to the local grid voltage

to avoid burning out the power supply;

●

If the local power grid voltage is within 200-240V,

please dial the power supply of the machine to 230V

(it is 230V by default).

●

If the local power grid voltage is within 100-120V,

please dial the power supply of the machine to 115V;

115V

230V

B2

B1

C

D

B3

A

14

4. Installing the 3D Printer