DG - 10/2019

http://www.end.de

21

Mounting / Disassembly

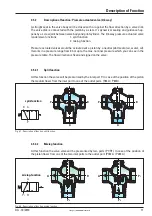

5.3.2

Protection of the sealings by disassembling the valve top

By welding the valve between the pipes you have to disassemble the valve top first, to prevent

the damage of the sealings.

5.3.2.1

Disassembly of the valve top

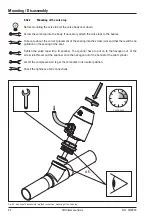

Clamp the valve between a vice carefully. By using guard plates you can prevent the damage of

the ends of the body.

At valves with the function „normally close“ we recommend to lift up the valve disk from the seat

(see also chapter 4.2 „Device variants“). Therefore you have to screw a appropriate hose con-

nector into the pilot port and to connect it with a compressed air hose.By feeding the hose with

compressed air with a maximum pressure of 6 bar the valve disk will lift up from the seat.

Loosen the valve top with a fit spanner. The spanner have to put on to the hexagon nut of the screw

joint.Never put the spanner on to the hexagon nut of the bonnet of the pilot cylinder.

Screw out the valve top of the valve body and take it by side carefully. Place a mark on the body and

the pilot cylinder that you will be able to join the correct parts by a subsequent mounting of valve.

Fig. 5.1 - mounting / disassembly - welded connection, desassembly of the valve top