AMETEK CTS

BS 200N100

Operating manual

V 1.12

6 / 21

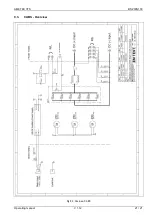

2.2.

Operating elements Front- and Rearside

Figure 2.2: BS 200N100 view left and right side

1

Power IN

+

2

Input DUT supply

-

IN

3

Monitor DUT output 1:200, 5%

4

Trigger OUT (15V neg. slope)

5

Trigger IN

(Pull down)

6

BS200N100 Power supply 24V DC

7

Output to DUT

+

8

Output to DUT

-

9

Reference earth connection

1

Power IN + supply

The battery supply

+

IN for the DUT is connected to this input. The switch is located between POWER

+

IN

and DUT

+

plug. The nominal dc supply parameters are 60V / 100A .

2

Power IN - supply

The battery supply

-

IN for the DUT is connected to this input. Internal is a direct connection to DUT- plug.

3

Monitor DUT

Monitor output for voltage measuring (divider 200:1, 5%). The monitor measures the voltage at the DUT

side. The BNC output plug is isolated.

For transient emission measuring an external voltage probe with >400MHz bandwidth must be used.

4

CRO Trigger OUT

Trigger output for an oscilloscope trigger. Trigger with a negative slope (+15V to 0V).

5

Trigger IN

The Trigger IN (Umax. +15V) has two different modes

1.

External trigger input for start a single switch event using the duration, setting with the potentiometer.

The trigger shall be a zero going signal (BNC to GND.

2.

Direct switch control ON/OFF (LV124 application)

The trigger controls direct the switch. This happens normally with the PFS 200 generator trigger out

signal. For set the BS 200N100 in this mode, the user must press during the power on time the

“Manual

Trigger”

button. A short LED blinking confirms the correct setting.

6

Power supply device 24V DC

Input plug for 24V dc supply 1A.

7

Output to DUT +

The DUT is connected at the banana output sockets

OUT

+

.

8

Output to DUT

-

The DUT is connected at the banana output sockets

OUT

-

.

9

Reference earth connection

The bottom plane is the reference GND of the BS 200N100 and must be connected to the ground reference

plane.