9

MicroVission Retrofit Instructions • 35391MVRF

WARNING

When handling microcontroller, use additional

personnel or lifting device as required. Failure to

comply may result in serious injury and/or damage to

equipment.

Step 4

. Mount the MicroVission bracket to the compressor frame with four (4) 3/4” bolts and hardware provided. If the

compressor base is filled with concrete the bracket can be welded to the compressor frame. Follow standard

practices for welding and fabrication procedures.

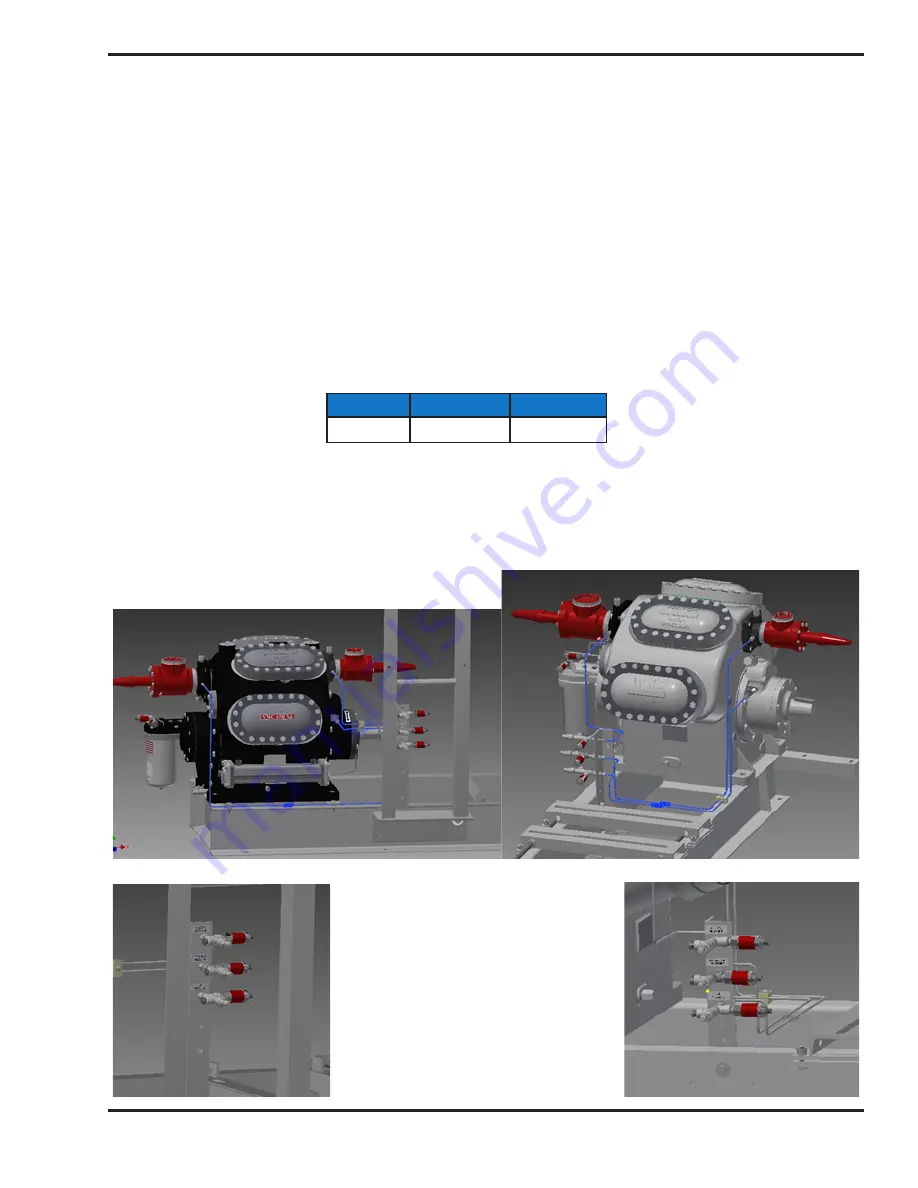

Figure 9. Tubing According to Compressor´s

Drive: Direct Drive (Left) & Belt Drive (Right)

Figure

10.

Direct

Drive

Transducer Mounting (left) and

Belt Drive Transducer Mounting

(right)

Step 5

. Mount the Block & Bleed bracket with valves and hardware from KT1133A9(A10) and install the pressure

transducers as shown as in Figure 9 and Figure 10.

Mount and install 1/4” ASTM A179 steel tubing (provided by others) between pressure transducers, suction,

discharge, and oil manifold connections.

Verify correct transducer pressure ranges:*

Suction

Discharge

Oil Manifold

0-200 psia 0-414.5 psia

0-200 psia

*0-414.5 psia intermediate on integral 2-stage compressors

NOTE

If excesive vibration occurs, further support from the

controller bracket to the base may be required