D & E

2-013

2-014

F 2-113

G 2-116

H 2-120

J 2-125

K 2-130

L 2-226

M 2-228

N 2-230

P 2-337

Q 2-346

R 2-352

T 2-438

Sapag Safety Valves Series 8400/8500/8490/8590

Installation and Maintenance Instructions

Emerson reserves the right to change the contents without notice

page 14

Assembly of Cap and Lifting Lever Devices

Series 8000 pressure relief valves are furnished with several different caps and lifting lever

devices. The following describes assembly of the available types of cap construction. (Disassembly

is the reverse of assembly). For part identification refer to Figure 13.

• Type B and K

Install the cap gasket and screw the cap onto the top of the bonnet. Tighten the cap with a strap

wrench. Install the cap plug gasket and screw cap plug into the cap. The test rod is installed only

during system hydrostatic testing. Never install the test rod unless performing system hydrostatic

testing.

• Type C

Screw the spindle nut onto the spindle.

Place the cap on the bonnet. Install the forked lever and forked lever pin. Attach the lever to the

cap using the lever pin and secure with the lever pin cotter.

Adjust the spindle nut until the forked lever rests on the lever and there is a 1/16 inch minimum of

play between the forked lever and the spindle nut. The spindle nut may be adjusted by removing

the forked lever pin, forked lever and cap. When the spindle nut is in proper adjustment, install the

spindle nut cotter pin. Replace the cap and forked lever and install the forked lever pin and forked

lever pin cotter.

Position the lever opposite the valve outlet and install the four (4) cap set screws and tighten them

against the groove in the top of the bonnet.

• Type D

Install the cap gasket on the bonnet. Screw the spindle nut onto the spindle. Place the dog in the

cap and install the dog shaft so that the dog is horizontal and the square on the end of the dog

shaft has a corner on top. With the dog shaft in the position above, scribe a horizontal line on the

end of the dog shaft. This line must be horizontal when the lifting gear is finally installed on the

valve. Install the dog shaft O-ring in the dog shaft bearing and place the dog shaft bearing gasket

on the dog shaft bearing.

Screw the dog shaft bearing into the cap. Rotate the dog shaft so that the dog is pointing down

and install the cap assembly onto the bonnet. Rotate the dog shaft so that the dog contacts the

spindle nut. With the scribed line horizontal, remove the assembly and adjust the position of the

spindle nut. Repeat the operation until the scribed line is horizontal when the dog contacts the

spindle. Remove the assembly and install the spindle nut cotter pin.

Install the lifting gear assembly onto the bonnet and secure it with cap studs and nuts.

For Type D lifting levers that have two part caps (cap and cap top) the above procedure is more

easily accomplished. After the cap is screwed to the bonnet, the positioning of the dog shaft is the

same as above except that the positioning of the spindle nut is performed last through the open

end of the cap.

With the dog in the horizontal position, screw the spindle nut onto the spindle until it contacts the

dog. Install the spindle nut cotter, cap top gasket and screw the cap top into the cap.

• Type E

Assembly of Type E lifting lever is identical to Type D with the addition of the cap plug gasket and

cap plug. The test rod is installed only during system hydrostatic testing. Never install the test rod

unless performing system hydrostatic test.

• Type H and M

Assembly of Type H and M is identical to Type G and L with the addition of the cap plug gasket

and cap plug. The test rod is installed only during system hydrostatic testing. Never install the test

rod unless performing system hydrostatic test.

Soft Seat Construction

Coat O-ring with Parker Super O-Lube and place a small amount of Loctite 242 (or equivalent

removable thread lock) onto retainer screw before assembly. Securely tighten retainer screw(s).

• O-Ring Soft Seats

Sapag Series 8000 metal-to-metal seated pressure relief valves may be converted to an O-ring

soft seat by replacing the standard disc insert and nozzle with those parts designed to house the

O-ring soft seat or vice versa.

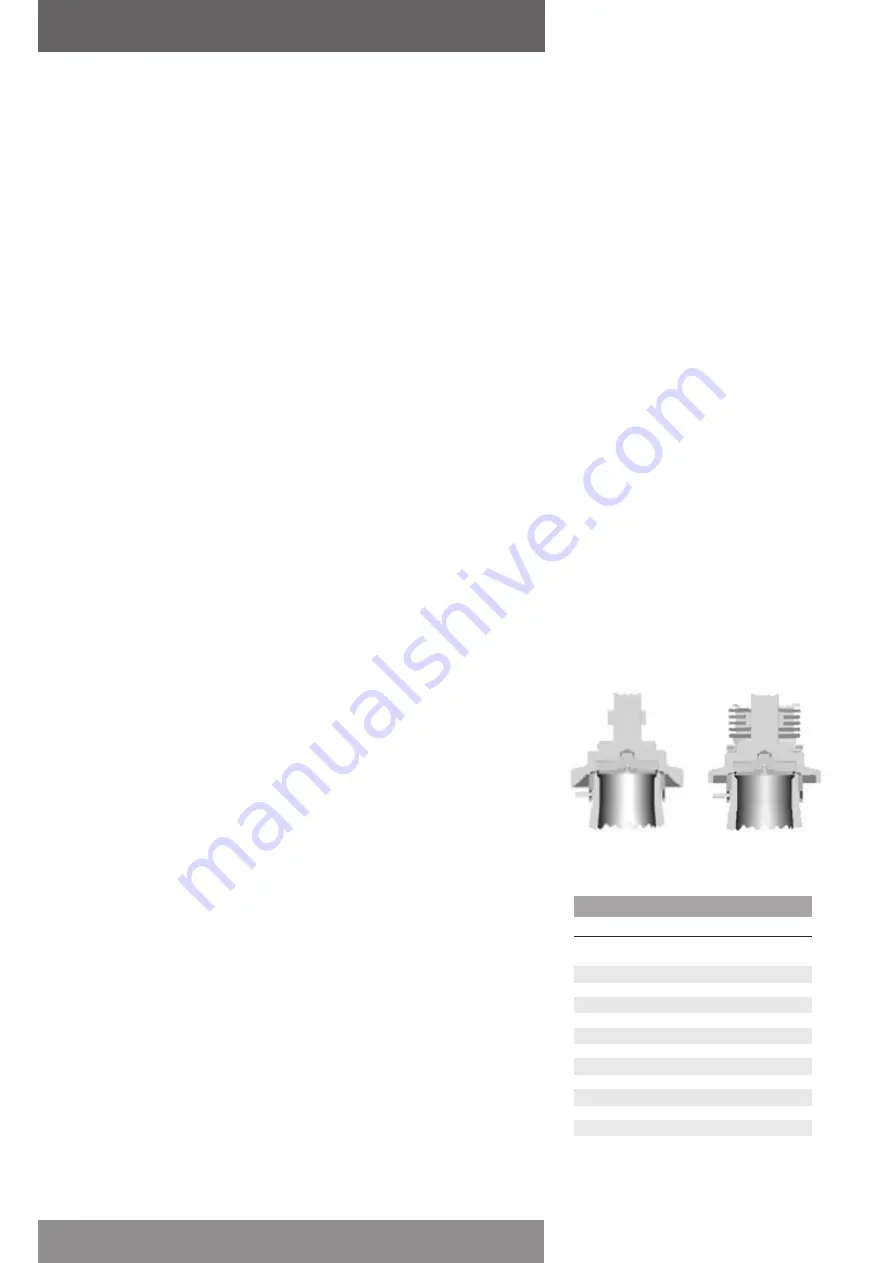

Figure 14

8500 O-ring

8400/8490

Soft seat

O-ring

Soft seat

Table 10 - soft seat o-ring sizes

Orifice

O-ring size

All Elastomers

Teflon Only