Configuring Your Neutral and Ground Connections

19

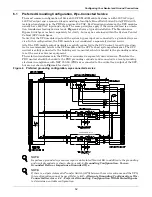

Figure 9

Preferred grounding configuration, impedance-grounded wye

These configurations have the same restrictions as explained in

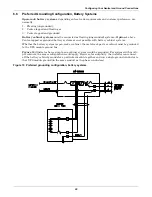

6.2 - Alternate Grounding Config-

uration, Wye-Connected Service

, except for the wye input. The UPS input and bypass must be fed

from the same source. The load must be strictly 3-wire. And the GFI time delay should be set to at

least 0.2 seconds to prevent tripping during transfer or retransfer operations.

!

CAUTION

Failure to properly set the ground fault interrupters could cause loss of power to the critical

load.

Summary of Contents for Liebert Series 610

Page 69: ...Installation Drawings 63 Figure 44 Battery power pack system 88 797616 03 Rev 08 ...

Page 70: ...Installation Drawings 64 Figure 45 Battery power pack Size A 88 797616 01 Rev 10 ...

Page 104: ...Installation Drawings 98 ...

Page 109: ...Site Planning Data Series 610 500 750kVA Multi Module Systems 103 NOTES ...

Page 110: ...Site Planning Data Series 610 500 750kVA Multi Module Systems 104 ...

Page 111: ......