S201 and S202 Series

2

Specifications

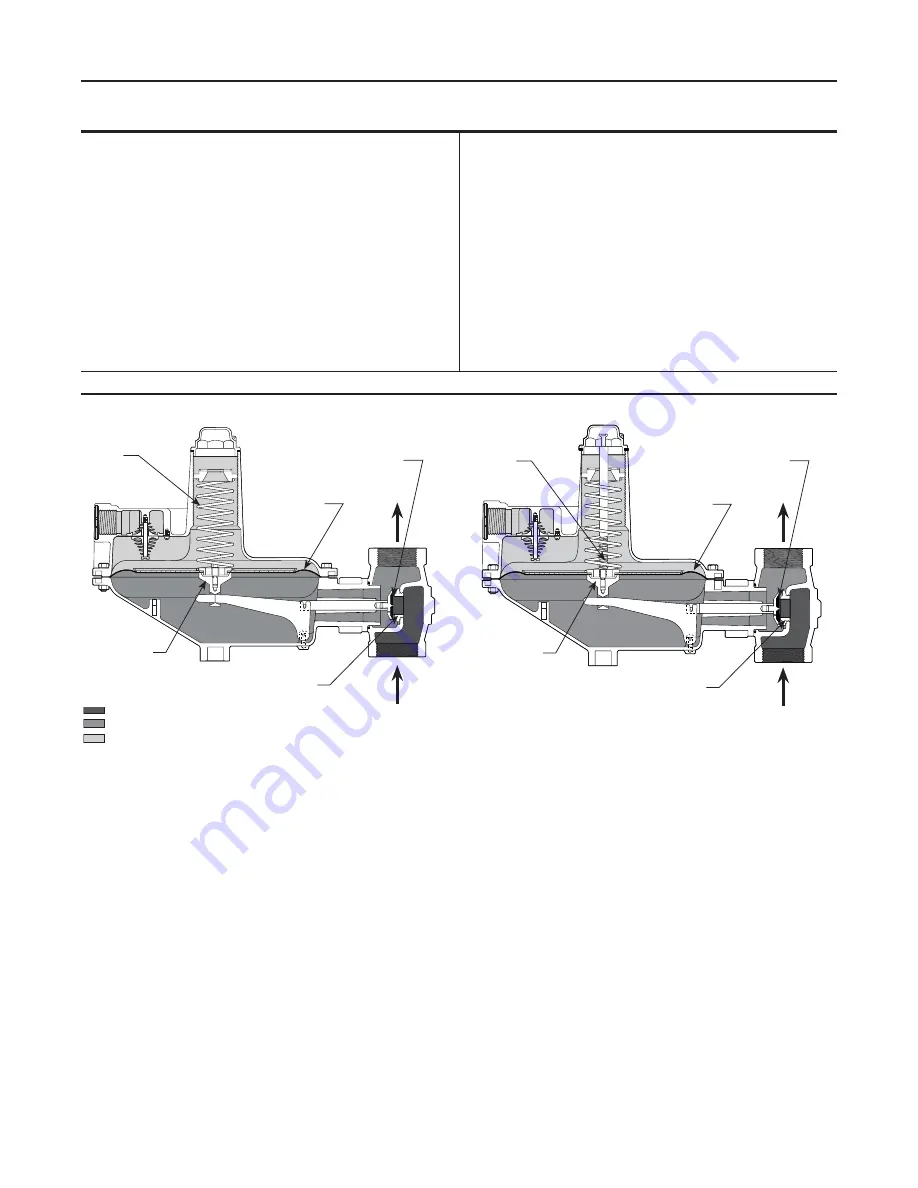

Principle of Operation

Refer to Figure 2. When downstream demand

decreases, the pressure under the diaphragm

increases. This pressure overcomes the regulator

setting (which is set by the control spring). Through

the action of the pusher post assembly, lever, and

valve stem, the valve disk moves closer to the orifice

and reduces gas flow. If demand downstream

increases, pressure under the diaphragm decreases.

Spring force pushes the pusher post assembly

downward, and the valve disk moves away from the

orifice, and the gas flow increases.

The Types S202 and S202H regulators include an

internal relief valve. Internal relief is used to help

minimize overpressure. Any outlet pressure above

the start-to-discharge point of the non-adjustable relief

spring moves the diaphragm off of the relief seat,

allowing excess pressure to discharge through the vent.

Typical start-to-discharge values are 7-inches w.c. to

2 psi (17 to 138 mbar) above the outlet pressure

setting, depending on control spring used.

Available Configurations

See Figure 3

Body Size and End Connection Styles

1-1/2 or 2 NPT inlet and outlet and

NPS 2 (DN 50) CL125 FF flanged

Maximum Allowable Inlet Pressures

(1)

See Table 1

Maximum Emergency Outlet Pressure

(1)

15 psig (1,0 bar)

Outlet Pressure Range

2.0-inches w.c. to 10 psig (5 mbar to 0,69 bar)

Orifice Size

1/4, 3/8, 1/2, 3/4, 1, and 1-3/16-inches

(6,4; 9,5; 13; 19; 25; and 30 mm)

Temperature Capabilities

-20° to 150°F (-29° to 66°C)

Pressure Registration

Internal

Approximate Weight

22 pounds (10 kg)

1. The pressure/temperature limits in this Instruction Manual and any applicable standard or code limitation for valve should not be exceeded.

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

A6198

Type S202

Figure 2. Operational Schematics

A6197

A6198

INLET PRESSURE

OUTLET PRESSURE

ATMOSPhERIC PRESSURE

CONTROL

SPRING

RELIEF vALvE

SPRING

PUShER POST

PUShER POST

DIAPhRAGM

DIAPhRAGM

vALvE DISk

vALvE DISk

ORIFICE

ORIFICE

TyPE S201

TyPE S202