S201 and S202 Series

4

Before installing the regulator, check for damage

which might have occurred in shipment. Also check

for dirt or foreign matter which may have accumulated

in the regulator body or in the pipeline. Apply pipe

compound to the external threads of the pipeline and

install the regulator so that flow is in the direction of

the arrow cast on the body. The diaphragm casing

assembly can be rotated to any position relative to the

body. Loosen the two cap screws (key 18, Figure 5) in

order to rotate the diaphragm casing assembly.

Do not install the regulator in a location where there

can be excessive water accumulation, such as directly

beneath a downspout.

If the regulator is used in conjunction with a Type 289H

relief valve, it should be installed as shown in Figure 4.

The outside end of the vent line should be protected

with a rainproof assembly.

The Type 289H should be set 10-inches w.c. (25 mbar)

higher than the outlet pressure setting of the regulator,

up to 30-inches w.c. (75 mbar) outlet pressure. For

pressure greater than this, set the Type 289H 0.75 psi

(0,05 bar) higher than the outlet pressure setting of

the regulator.

The S201 and S202 Series regulators have 1 NPT

screened vent openings in the spring case. If

necessary to vent escaping gas away from the

regulator, install a remote vent line in the spring

case tapping. Vent piping should be as short and

direct as possible with a minimum number of bends

and elbows. The remote vent line should have the

largest practical diameter. Vent piping on regulators

with internal relief (Types S202 and S202H) must

be large enough to vent all relief valve discharge to

atmosphere without excessive backpressure and

resulting excessive pressure in the regulator.

Periodically check all vent openings to be sure that

they are not plugged.

Maximum outlet pressure settings are shown in

Table 2. Outlet pressure more than 2 psi (0,14 bar)

(light diaphragm head) or 3 psi (0,21 bar) (heavy

diaphragm head) above the setpoint may damage

internal parts such as the diaphragm head and valve

disk.

The maximum emergency (casing) outlet

pressure is 15 psig (1,0 bar).

Startup

CAUTION

Pressure gauges should always be used

to monitor downstream pressure during

startup. Procedures used in putting this

regulator into operation must be planned

accordingly if the downstream system is

pressurized by another regulator or by a

manual bypass.

If the downstream system is not pressurized by

another regulator or manual bypass valve, use the

following procedure to startup the regulator.

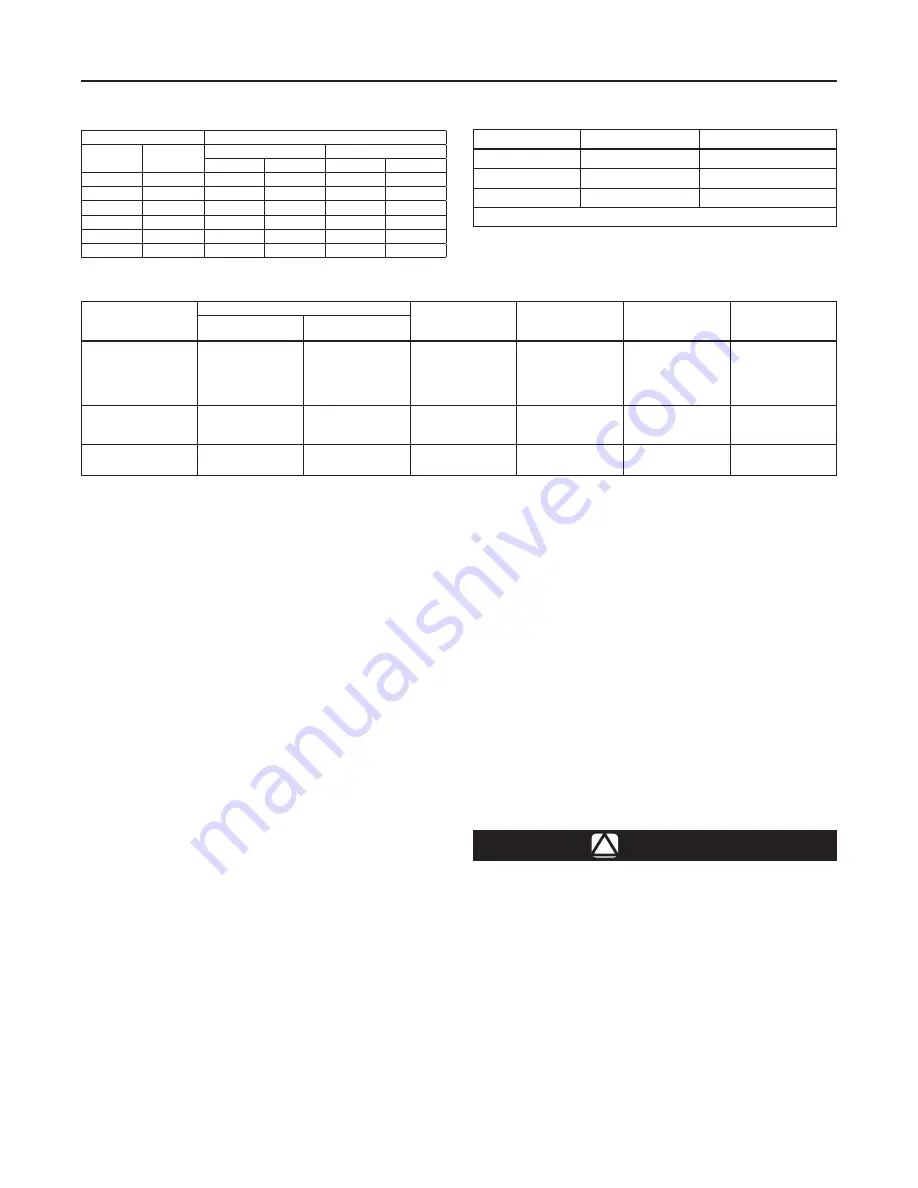

Table 1. Maximum Allowable Inlet Pressures

Table 2. Maximum Outlet Pressure Setting

ORIFICE SIzE

INLET PRESSURE SETTING

Inches

mm

Optimum

Maximum

Psig

bar

Psig

bar

1/4

6,3

125

8,6

125

8,6

3/8

9,5

100

6,9

125

8,6

1/2

13

60

4,1

100

6,9

3/4

19

25

1,7

60

4,1

1

25

13

0,90

25

1,7

1-3/16

30

5

0,34

13

0,90

TyPE NUMBER

DIAPhRAGM hEAD

MAxIMUM OUTLET*

S201, S202

Light

30-inches w.c. (75 mbar)

S201H, S202H

Heavy

5 psig (0,34 bar)

S201K

Heavy

10 psig (0,69 bar)

* Maximum emergency outlet (casing) pressure for S200 Series is 15 psig (1,0 bar).

Table 3. Outlet Pressure Ranges

TyPE NUMBER

SPRING RANGE

PART NUMBER

SPRING FREE

LENGTh,

INChES (mm)

SPRING WIRE

DIAMETER,

INChES (mm)

COLOR CODE

Inches w.c.

mbar

S201 and S202

2.0 to 4.5

3.5 to 6.5

5.0 to 9.0

8.5 to 18.0

14.0 to 30.0

5 to 11

9 to 16

12 to 22

21 to 45

35 to 75

1D892527022

1D892627022

1D892727012

1D893227032

1D893327032

6.12 (155)

7.53 (191)

7.88 (200)

7.50 (191)

7.25 (184)

0.109 (2,77)

0.112 (2,84)

0.130 (3,30)

0.156 (3,96)

0.182 (4,62)

Brown

Red

Black

Gray

Dark Green

S201H and S202H

1.0 to 2.0 psig

1.5 to 3.25 psig

2.0 to 5.0 psig

0,07 to 0,14 bar

0,10 to 0,22 bar

0,14 to 0,34 bar

1H975827032

1H975927032

1P615427142

7.09 (180)

6.91 (176)

6.50 (165)

0.225 (5,72)

0.250 (6,35)

0.295 (7,49)

Dark Blue

Orange

Yellow

S201K

2.0 to 5.5 psig

4.0 to 10.0 psig

0,14 to 0,38 bar

0,28 to 0,69 bar

0Y066427022

1H802427032

6.00 (152)

6.00 (152)

0.363 (9,22)

0.406 (10,3)

Green Stripe

Cadmium