Instruction Manual

D200124X012

2500 and 2503 Controllers/Transmitters

June 2017

24

D

For Direct Acting 2500, 2500T,

0.2 bar

(3 psig) for a 0.2 to 1.0 bar (3 to 15 psig) output or 0.4 bar (6 psig) for a 0.4 to

2.0 bar (6 to 30 psig) output.

D

For Reverse Acting 2500, 2500T

, 1.0 bar (15 psig) for a 0.2 to 1.0 bar (3 to 15 psig) output or 2.0 bar (30 psig) for a

0.4 to 2.0 bar (6 to 30 psig) output.

6. Visually examine the nozzle and flapper to ensure the nozzle is as square as possible with the flapper. The nozzle can

be realigned by loosening the Bourdon tube mounting screws (key 45, figure 16) and rotating the Bourdon tube

slightly. If the nozzle is realigned, tighten the mounting screws and repeat step 5.

7. Set the process variable to the maximum value of the input range as shown in table 6.

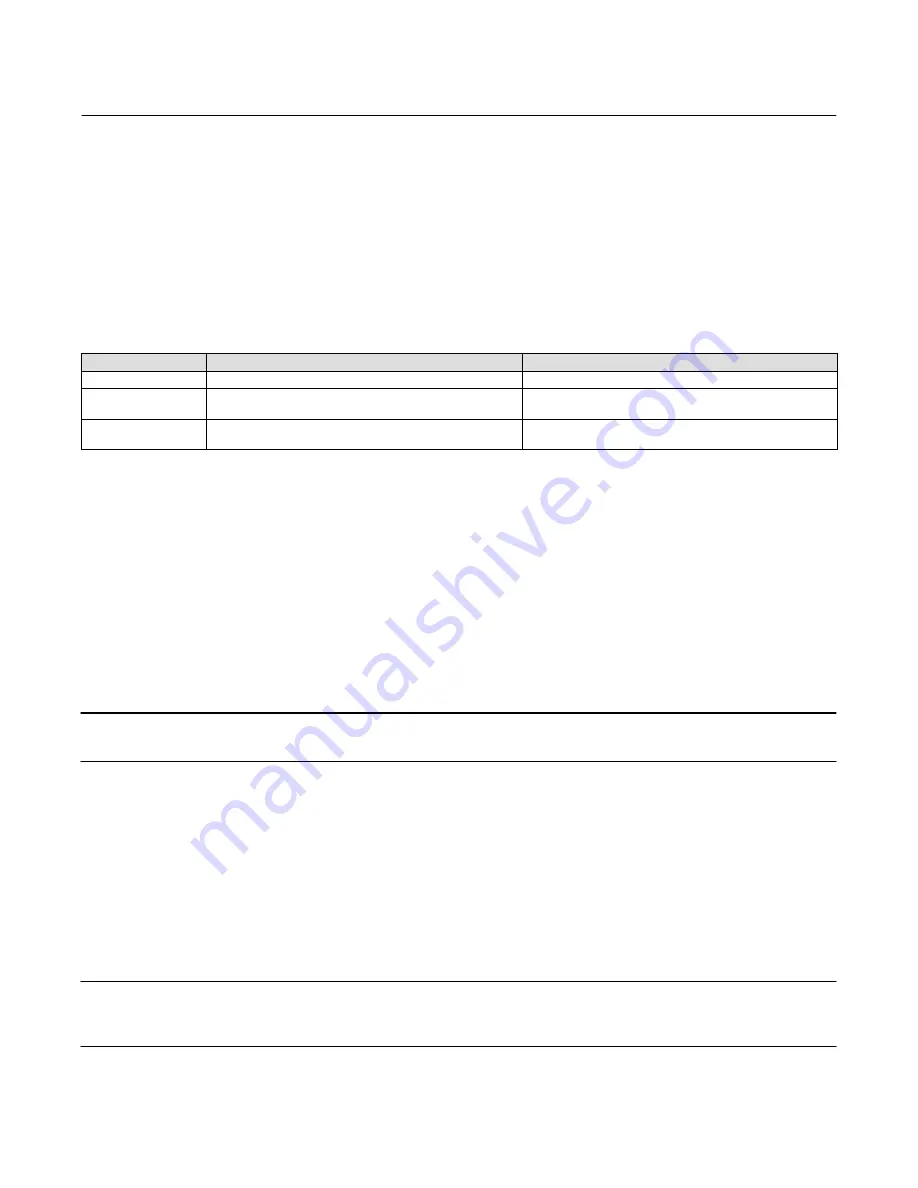

Table 6. Minimum and Maximum Limits for Setting Process Variables

Application

Minimum Limit

Maximum Limit

Liquid Level

Displacer must be completely out of liquid

Displacer must be completely submerged in liquid

Interface

Displacer must be completely submerged in lighter of two

process liquids

Displacer must be completely submerged in

heavier of two process liquids

Density

Displacer must be completely submerged in liquid having

specific gravity of lowest range point

Displacer must be completely submerged in liquid having

specific gravity of highest range point

8. The output pressure should be:

D

For Direct Acting 2500, 2500T

, 1.0 bar (15 psig) for a 0.2 to 1.0 bar (3 to 15 psig) output or 2.0 bar (30 psig) for a 0.4

to 2.0 bar (6 to 30 psig) output.

D

For Reverse Acting 2500, 2500T

, 0.2 bar (3 psig) for a 0.2 to 1.0 bar (3 to 15 psig) output or 0.4 bar (6 psig) for a 0.4

to 2.0 bar (6 to 30 psig) output.

10. If the unit does not contain an indicator assembly, go to the Startup section. If the unit contains an indicator

assembly, change the pointer span by loosening the indicator plate screws (key 41, figure 16, detail of indicator

assembly), slide the plate until the HIGH mark is under the pointer. Tighten the plate screws and go to the Startup

section.

Note

strip base (key 27) right or left along the elongated slotted hole as follows:

D

To

increase

the output pressure span, slide the flexure strip base away from the torque tube shaft.

D

To

decrease

the output pressure span, slide the flexure strip base toward the torque tube shaft.

Retighten the screws. If the flexure strip base has been moved as far as possible and the output pressure span is still

too large or too small, proceed to step 13.

12. Repeat the procedure from step 4 until the required calibration points are obtained.

Note

Any change of the PROPORTIONAL BAND or SPECIFIC GRAVITY adjustment in the following step changes the zero as well as the

output pressure span.