6-3

L2650EA

The following adjustment normally are not

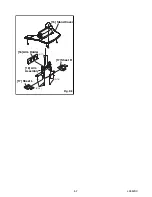

attempted in the field. Only when replacing the

LCD Panel then adjust as a preparation.

3. White Balance Adjustment 1

Purpose:

To mix red, green and blue beams correctly

for pure white.

Symptom of Misadjustment:

White becomes bluish

or reddish.

Note:

Use the remote control unit.

1. Operate the unit for more than 20 minutes.

2. Input the White Purity (APL 80%).

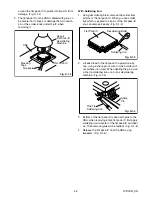

3. Set the color analyzer to the CHROMA mode and

bring the optical receptor to the center on the

LCD-Panel surface after zero point calibration as

shown above.

Note:

The optical receptor must be set

perpendicularly to the LCD Panel surface.

4.

[VIDEO1]

Enter the Service mode. Press “VOL

p

” button on

the remote control unit and select “C/D1-” mode.

[VIDEO2]

Enter the Service mode. Press “VOL

p

” button on

the remote control unit and select “C/D2-” mode.

5.

[VIDEO1]

Press “6” button to select “DB(C/D1)” for Blue

adjustment. Press “4” button to select “DR(C/D1)”

for Red adjustment. When “x” value and “y” value

are not within specification, adjust “DB (C/D1)” or

“DR (C/D1)”. Refer to “1. Initial Setting.”

Note:

“DB(C/D1)” or “DR(C/D1)” must be adjusted

within ±0.005.

[VIDEO2]

Press “6” button to select “DB(C/D2)” for Blue

adjustment. Press “4” button to select “DR(C/D2)”

for Red adjustment.When “x” value and “y” value

are not within specification, adjust “DB(C/D2)” or

“DR(C/D2)”. Refer to “1. Initial Setting.”

Note:

“DB(C/D2)” or “DR(C/D2)” must be adjusted

within ±0.005.

6. Turn the power off and on again. (Main power

button on the TV unit.)

4. White Balance Adjustment 2

Purpose:

To mix red, green and blue beams correctly

for pure white.

Symptom of Misadjustment:

White becomes bluish

or reddish.

Note:

Use the remote control unit.

1. Operate the unit for more than 20 minutes.

2. Input the White Purity (APL 20%).

3. Set the color analyzer to the CHROMA mode and

bring the optical receptor to the center on the

LCD-Panel surface after zero point calibration as

shown above.

Test Point Adj. Point

Mode

Input

Screen

VOL.

p

buttons

[VIDEO1]

C/D1

[VIDEO2]

C/D2

White Purity

(APL 80%)

M. EQ.

Spec.

Pattern Generator,

Color analyzer

x: 0.271 to 0.281,

y: 0.277 to 0.287

Figure

Color Analyzer

It carries out in a darkroom.

L = 3 cm

Perpendicularity

INPUT: WHITE 80%

Test Point Adj. Point

Mode

Input

Screen

VOL.

p

buttons

[VIDEO1]

C/D1

[VIDEO2]

C/D2

White Purity

(APL 20%)

M. EQ.

Spec.

Pattern Generator,

Color analyzer

x: 0.271 to 0.281,

y: 0.277 to 0.287

Figure

Color Analyzer

It carries out in a darkroom.

L = 3 cm

Perpendicularity

INPUT: WHITE 20%

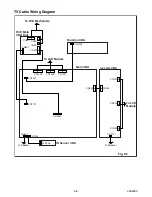

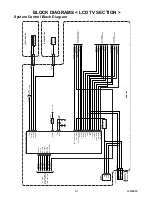

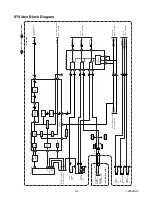

Summary of Contents for EWL20D6

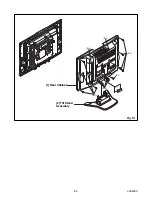

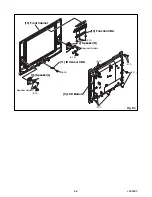

Page 17: ...5 3 L2652DC 1 Rear Cabinet S 2 S 1 S 1 S 3 S 1 S 1 Fig D1 2 Tilt Stand Assembly ...

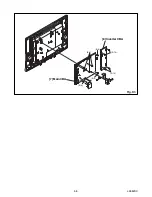

Page 19: ...5 5 L2652DC 7 Main CBA 8 Inverter CBA S 9 S 9 S 9 S 9 S 10 S 10 Fig D3 ...

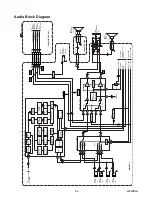

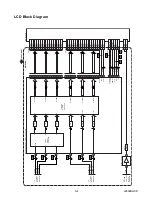

Page 40: ...10 3 Main 1 6 Schematic Diagram LCD TV Section L2652SCM1 ...

Page 41: ...10 4 L2652SCM2 Main 2 6 Schematic Diagram LCD TV Section ...

Page 42: ...10 5 Main 3 6 Schematic Diagram LCD TV Section L2652SCM3 ...

Page 43: ...10 6 L2652SCM4 Main 4 6 Schematic Diagram LCD TV Section ...

Page 45: ...10 8 L2652SCM6 Main 6 6 Schematic Diagram LCD TV Section ...

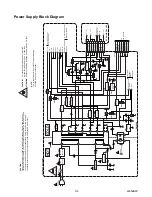

Page 46: ...10 9 L2652SCF Function Schematic Diagram LCD TV Section ...

Page 47: ...10 10 L2652SCIR IR Sensor Schematic Diagram LCD TV Section ...

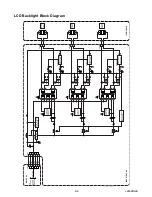

Page 48: ...10 11 L2652SCI Inverter Schematic Diagram LCD TV Section ...

Page 50: ...10 13 L2652SCD2 DVD Main 2 3 Schematic Diagram DVD Section ...

Page 51: ...10 14 L2652SCD3 DVD Main 3 3 Schematic Diagram DVD Section ...

Page 55: ...10 18 Inverter CBA Top View BL2500F01021 Inverter CBA Bottom View ...

Page 74: ...EWL20D6 L2652UC 2006 06 26 ...