7

8 Series

Maintenance

WARNING

!

Flame cells must be inspected for

damage immediately following a

deflagration and/or stabilized burn.

1. Carefully remove the element assembly from

the arrestor and place it on a soft surface such

as plywood.

2.

Inspect the flame cell visually for any signs of

corrosion or other damage.

3.

Inspect the flame cell with a calibrated pin gauge

to ensure maximum crimp size openings do not

exceed the following values for their respective

gas group:

• Explosion Group D – 0.062 in. / 1.57 mm

• Explosion Group C – 0.038 in. / 0.965 mm

• Explosion Group B – 0.017 in. / 0.432 mm

4.

If any damage is noted, or crimp openings

exceed maximum size allowable, replace the

element assembly.

5. Keep the element openings clean to prevent

loss of efficiency in absorbing heat. Remove the

element assembly and clean the elements to

prevent the openings from becoming clogged

with particulate matter. Clean the element with a

suitable cleaning media (solvent, soap, water, or

steam) then blow dry using compressed air. Be

careful not to damage or dent the cell openings

as this would hamper the effectiveness of the unit.

Do not clean the arrestor elements by rodding to

remove blockages, as this practice will damage

the elements and seriously impair the arrestor’s

performance. If the arrestor element cannot be

cleaned satisfactorily, replace it.

6.

For best cleaning results, use a high pressure

sprayer with spray wand (1500 to 3000 psig /

103 to 207 bar) to clean the entire element

surface. Hold the spray nozzle perpendicular

to the surface being cleaned to maximize spray

media penetration into the element. Alternately

spray each side of the element surface until clean.

7. The cleaning interval should be governed by the

amount and type of particulate in the system to

which it is installed and must be determined by

the user. To determine the maintenance interval

the user should check the element in the first few

months of operation to find how quickly particulate

accumulates in the cells.

8.

After cleaning, thoroughly inspect the element for

damage. If damaged, replace it.

Note

Under no circumstance should the

element bank be disassembled from its

shell for cleaning or replacement. The

element section must be replaced as a

complete assembly.

Cleaning of units equipped with this

system may be accomplished in several

ways including periodic cleaning using

manually operated valves, by use of

an automated cycle timing method,

or by having the cleaning operation

initiated whenever the pressure loss

across the arrestor element exceeds a

predetermined value.

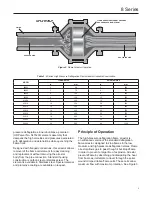

Element Assembly, Disassembly and

Reassembly Instructions

WARNING

!

Isolate gas supply and bring system

to atmospheric pressure to prevent

ignitable gas from flashing while

performing maintenance.

1. Loosen all jacking (inside) nuts on tension studs

between conical sections of the flame arrestor.

2. Tighten the inside jacking nuts on the tension

studs forcing the two conical sections apart. When

the two flange faces have separated, remove the

tension studs that do not have inside jacking nuts,

so that the element assembly can be removed.

The inside jacking nuts are installed on all tension

studs that facilitate jacking the unit apart. The

inside jacking nuts are not installed on tension

studs that are taken out, for ease of removal.