8 Series

6

Standard compressed fiber gaskets that will

withstand temperatures of 450°F / 232°C or higher

are normally used, but other materials of equal or

higher temperature capability may be used at the

customer’s discretion.

Positioning

CAUTION

The high pressure deflagration

flame arrestor is fitted with lugs for

lifting the element assembly during

servicing operations. These lugs are

not intended for lifting the entire unit

during installation. Damage to the high

pressure deflagration flame arrestor may

result from improper lifting. The units

should be lifted using appropriately

rated Nylon (PA) straps rigged on the

outside of the tension studs.

The arrestor should be positioned such that the

element is accessible for removal. The tension studs

are supplied with jacking nuts on one half of the bolting

circumference. Install the unit so that the jacking nuts

(on the inside of the studs) are positioned on the

opposite side from the direction that the element

assembly will be removed.

Models that have drain plugs are designed for

horizontal installation and should be installed with the

drain plugs aligned at the bottom of the unit. Models

that have pressure taps are designed to allow pressure

gauges to be installed on both sides of the flame cell

assembly to determine blockage. The pressure taps

should be aligned at the top to allow easy viewing

of the gauges. Units that are equipped with optional

internal cleaning systems should be connected to a

source of cleaning media such as water, steam or

other suitable solvent.

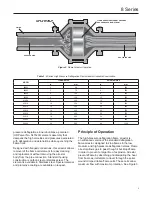

Flow Direction

The Enardo high pressure deflagration flame arrestor

is bi-directional and can be installed either vertically or

horizontally. Consideration should be given to non-

symmetrical assemblies that include features such

as clean-out ports, temperature monitoring device or

other options that might have a preferred installation

direction to suit the needs of the customer.

Piping Expansions and Reductions

Adjacent to High Pressure Deflagration

Flame Arrestors

WARNING

!

No instrument, tubing or other device

whatsoever shall circumvent the high

pressure deflagration flame arrestor

in such a manner to allow a flame path

to exist around the flame element of

the arrestor. When instrumentation is

installed in such a manner that it creates

a path circumventing the flame element

of an arrestor, measures must be taken

to prevent passage of flame through the

instrumentation device and/or system.

Instrumentation must be capable

of withstanding the maximum and

minimum pressures and temperatures to

which the device may be exposed and at

a minimum be capable of withstanding

a hydrostatic pressure test of 350 psig /

24 bar.

An Enardo high pressure deflagration flame arrestor

may be installed in any vapor control line that is

smaller than or equal to the nominal pipe diameter of

the arrestor’s connection flanges.

When it is necessary to increase the diameter of the

piping on the downstream side of the high pressure

deflagration flame arrestor, a length of pipe at least

120 pipe diameters must be installed between the

high pressure deflagration flame arrestor and the

expansion. A pipe diameter is considered as the

inside diameter of pipe having a nominal size equal

to the high pressure deflagration flame arrestor’s

connecting flanges.