1592026601 XWi70K STD FULL EN r1.6 2022.07.29.docx

XWi70K

8/15

16.6

DEFROST CONTROL (dEF)

It starts a defrost if there are the right conditions. After the defrost is finished, the normal regulation will

restart only if the digital input is disabled otherwise the instrument will wait until the

MdF

safety time is

expired.

16.7

ENERGY SAVING (ES)

The Energy Saving function allows to change the set point value as the result of the

SET+HES

(parameter) sum. This function is enabled until the digital input is activated.

16.8

HOLIDAY MODE (HdF)

Holiday mode activation.

16.9

REMOTE LIGHT CONTROL (LIG)

To manage the light activation from remote.

16.10

REMOTE ON OFF (onF)

To issue a remote ON/OFF command.

16.11

PARAMETER MAP CHANGE (Lnt)

To change the used parameter map from

nt

(first configuration or “normal temperature”) to

Lt

(second

configuration or “low temperature”) and vice

-versa.

16.12

DIGITAL INPUTS POLARITY

The digital input polarity depends on the

i1P

or

i2P

parameters:

i1P or i2P=CL:

the input is activated by closing the contact.

i1P or i2P=OP:

the input is activated by opening the contact

17

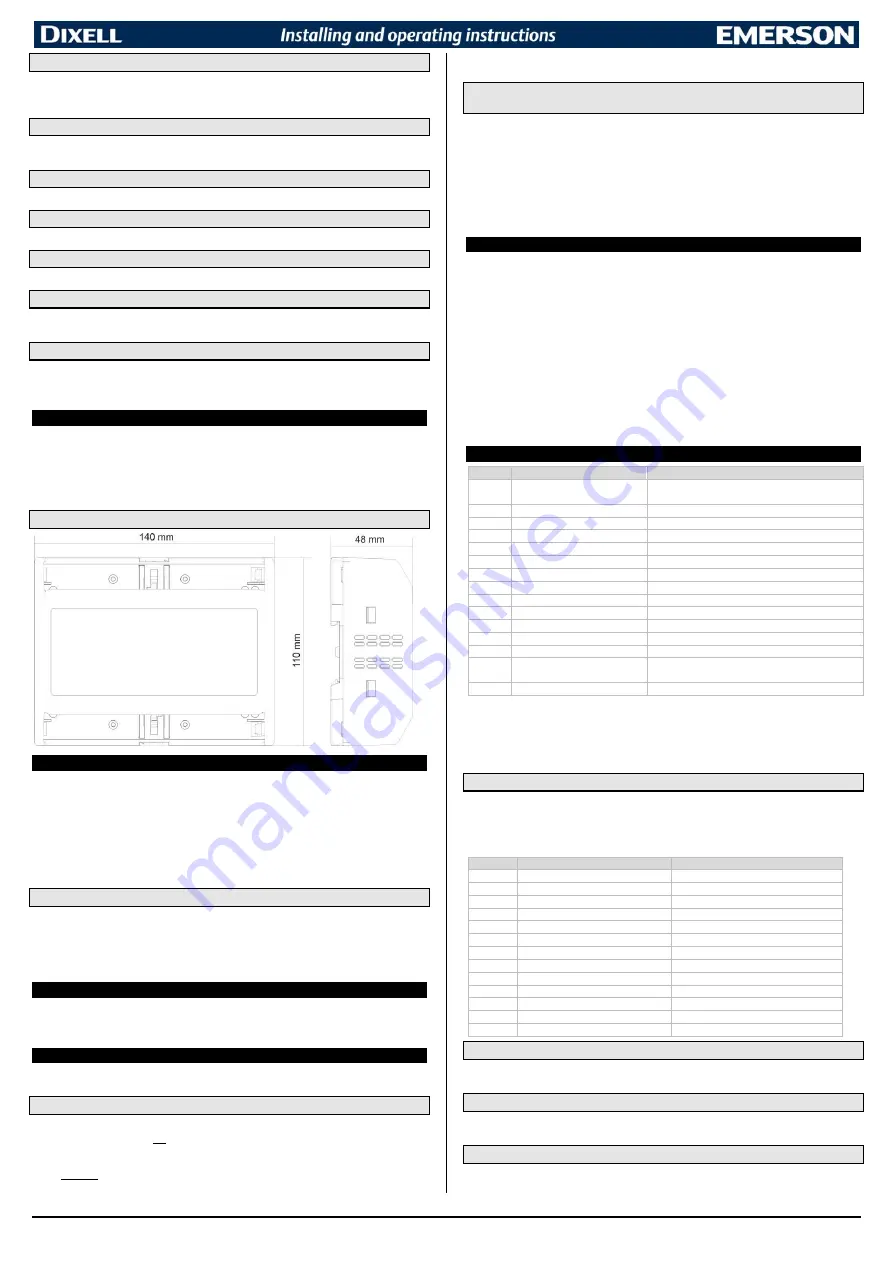

HOW TO INSTALL AND MOUNT

The controller

XWi70K

shall be mounted in a din rail and in a horizontal position or with the relay output

on the bottom side (IEC/60730).

It must be connected to the keyboard by using a 2-wire cable (

1mm). The temperature range allowed

for correct operation is 0 to 60°C. Avoid places subject to strong vibrations, corrosive gases, excessive

dirt or humidity. The same recommendations apply to probes. Let the air free to circulate by the aeration

holes.

17.1

XWi70K

–

8 DIN CASE - DIMENSIONS

18

ELECTRICAL CONNECTIONS

XWi70K

is provided with screw terminal blocks to connect cables with a cross section up to 2.5 mm

2

for

the RS485 (optional) and the keyboard. To connect the other inputs, power supply and relays,

XWi70K

is provided with Plug-in connections (6.3mm). Heat-resistant cables must be used. Before connecting

cables make sure the power supply complies with the instrument’s requirements. Separate the probe

cables from the power supply cables, from the outputs and the power connections. Do not exceed the

maximum current allowed, in case of heavier loads use a suitable external relay.

NOTE:

-

The maximum current allowed for the common line of the relays is 14A (IEC/60730)

-

The maximum current allowed for insulated relay (oA5) is 3A (IEC/60730)

18.1

PROBE CONNECTIONS

The probes shall be mounted with the bulb upwards to prevent damages due to liquid infiltration. It is

recommended to place the thermostat probe away from air streams to correctly measure the average

room temperature. Place the defrost termination probe among the evaporator fins in the coldest place,

where most ice is formed, far from heaters or from the warmest place during defrost, to prevent

premature defrost termination.

19

TTL/RS485 SERIAL LINE

The TTL connector allows, by means of the external module TTL/RS485

(XJ485CX)

, to connect the unit

to a network line

ModBUS-RTU

compatible as the

Dixell

monitoring system. The same TTL connector

is used to upload and download the parameter list of the “

HOT-KEY

”.

20

HOW TO

USE OF THE “HOT KEY”

NOTE: the XWi controllers need a 64KB HOT KEY (Dixell code:

DK00000300

). Standard Hot Key is not

supported.

20.1

PROGRAM A HOT-KEY FROM AN INSTRUMENT (UPLOAD)

1.

Program one controller with the front keypad.

2.

When the controller is ON

, insert the “

HOT-KEY

” and push

UP

button; t

he “

uPL

”

message

appears followed a by a flashing “

End

” label.

3.

Push

SET

button and the “

End

” will stop flashing.

4.

Turn OFF

the instrument, remove the “

HOT-KEY

” and

then turn it ON again.

NOTE

: the “

Err

” message appears in case of a failed programming opera

tion. In this case push again

button if you want to restart the upload again or remove the “

HOT-KEY

” to abort the operation.

20.2

HOT TO CHANGE PARAMETER MAP BY USING AN HOT-KEY

(DOWNLOAD)

1.

Turn OFF the instrument.

2.

Insert a

pre-programmed

“

HOT-KEY

”

into the 5-PIN port

and then turn the Controller ON.

3.

The parameter list of the “

HOT-KEY

” will be automatically downloaded into the Controller

memory. The “

doL

” message will blink followed a by a flashing “

End

” label.

4.

After 10 seconds the instrument will restart working with the new parameters.

5.

Remove the “

HOT-KEY

”.

NOTE:

the message “

Err

” is displayed for failed programming. In this case turn the unit off and then on

if you want to restart the download again or remov

e the “

HOT-KEY

” to abort the operation.

21

INTERNAL MEMORY

The controller has an internal memory where are stored:

-

Parameter maps

nt

and

Lt

-

Factory default configurations for both

nt

and

Lt

parameters map

The controller is always shipped with:

-

Parameter map

nt

= factory default configuration “

nt

”

-

Parameter map

Lt

= factory default configuration “

Lt

”

Any modification to parameter map

nt

or

Lt

does not change factory values.

It will be possible to restore factory defaults values for

nt

or

Lt

parameters map by using

UP2=CC

function.

NOTES:

-

If controller is using

nt

parameter map, the factory default configuration

nt

will be reloaded

overwriting

nt

parameter map. The same for parameter map

Lt

.

-

The factory default configurations are read only (it is not possible to modify them on the field).

22

ALARM SIGNALS

Message Cause

Outputs

P1

Thermostat probe failure

Alarm output ON; Compressor output according to

parameters

Con

and

CoF

P2

Second probe failure

Alarm output ON; Other outputs unchanged

P3

Third probe failure

Alarm output ON; Other outputs unchanged

P4

Fourth probe failure

Alarm output ON; Other outputs unchanged

HA

Maximum temperature alarm

Alarm output ON; Other outputs unchanged

LA

Minimum temperature alarm

Alarm output ON; Other outputs unchanged

HA2

Condenser high temperature

It depends on the

AC2

parameter

LA2

Condenser low temperature

It depends on the

bLL

parameter

dA

Door open

Compressor and fans restarts

EA

Warning

Output unchanged

CA

Lock alarm (i1F=bAL)

All outputs OFF

CA

Pressure switch alarm (i1F=PAL) All outputs OFF

EE

Data or memory failure

Alarm output ON; Other outputs unchanged

noL

No communication between base

and keyboard

Unchanged

EC1

VSC communication error

Unchanged

The alarm message is displayed until the alarm condition is recovery.

All the alarm messages are showed alternating with the room temperature except for the “P1” which is

flashing.

To reset the “EE” alarm and restart the normal functioning press any key, the “

rSt

” message is displayed

for about 3 sec.

22.1

SERIAL COMPRESSOR AND MODBUS FAN MANAGEMENT

The following table shows the managed alarms and errors when the serial compressor or the serial fan

control is used.

-

EMB1 or 2:

indication valid for Embraco compressor 1 or 2

-

SCP1 or 2:

indication valid for SECOP compressor 1 or 2

Message

Cause

Outputs

EC1

EMB1 or 2: communication error

Regulation stopped, retry function active

CP1, CP2

EMB1 or 2: compressor stopped

Regulation stopped, retry function active

HP1, HP2

EMB1 or 2: start fail

Regulation stopped, retry function active

E11, E21

EMB1 or 2: overload

Regulation stopped, retry function active

E12, E22

EMB1 or 2: under speed

Regulation stopped, retry function active

E13, E23

EMB1 or 2: wrong rotor position

Regulation stopped, power off required

E14, E24

EMB1 or 2: short circuit

Regulation stopped, power off required

HT1, HT2

EMB1 or 2: high temperature

Regulation stopped, retry function active

EC2

SCP1 or 2: communication error

Regulation stopped, retry function active

EV1, EV2

SCP1 or 2: voltage error

Regulation stopped, retry function active

EM1, EM2

SCP1 or 2: motor error

Regulation stopped, retry function active

ET1, ET2

SCP1 or 2: internal temperature error Regulation stopped, retry function active

CSr

Condenser fan maintenance

Unchanged, warning reset required

22.2

BUZZER MUTING

Once the alarm signal is detected the buzzer can be silenced by pressing any key. Buzzer is mounted

in the keyboard and it is an option.

22.3

“EE” ALARM

The

Dixell

instruments are provided with an internal check for the data integrity. The “EE” alarm flashes

when a failure in the memory data occurs. In such cases the alarm output is enabled.

22.4

ALARM RECOVERY

Probe

alarms: “

P1

” (probe1 faulty), “

P2

”, “

P3

” and “

P4

”; they automatically stop 10 sec after the probe

restarts normal operation. Check connections before replacing the probe.