User Manual

Introduction

QCL-MAN -CT2211-Aerosol-Leak-Detection-System-Rev F

October 2015

Introduction

7

1.6

Detailed system specification

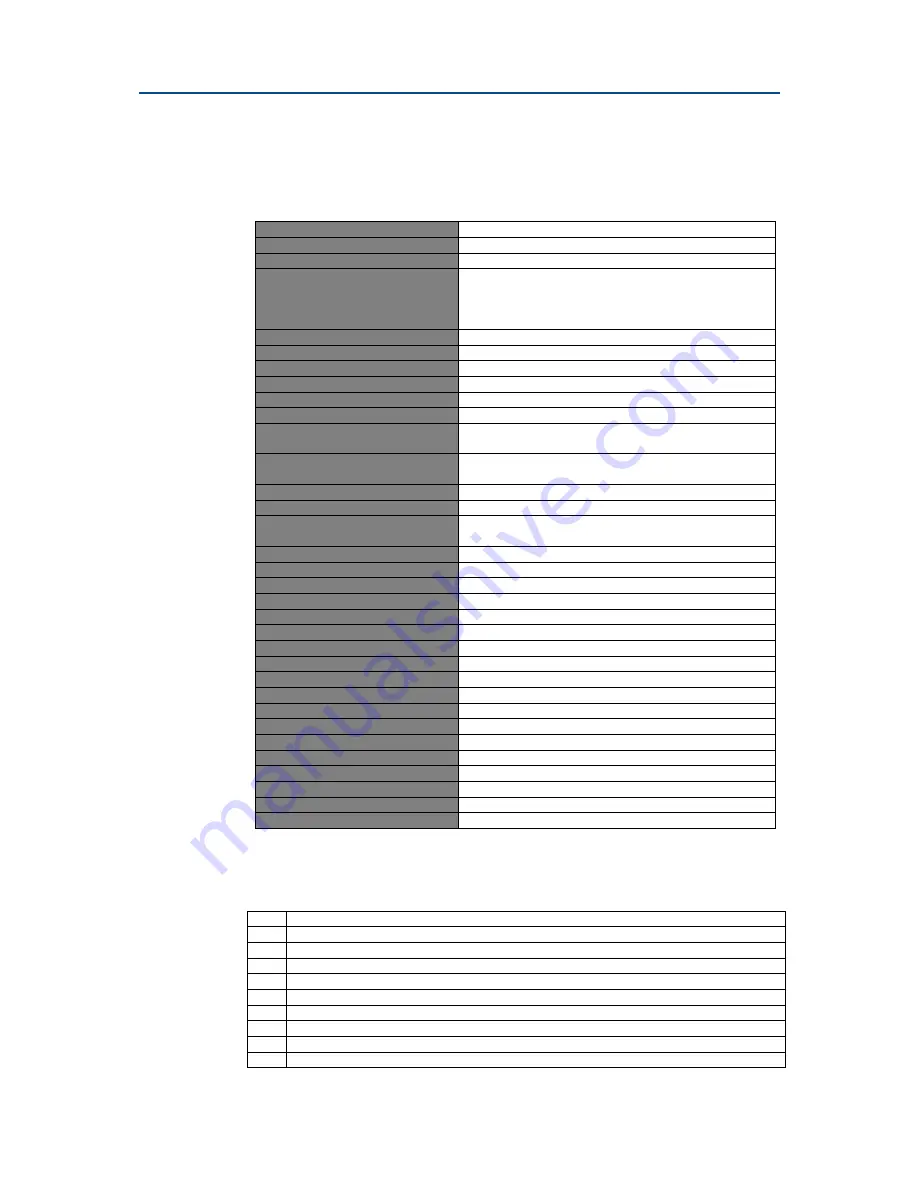

The following table shows the general characteristics of the leak detection system.

Table 1-1 Leak detection system specifications

Application

Leak detection system

Measurement technique

IR absorption spectroscopy

IR source

Quantum cascade laser

Laser classification

Class1

BS EN 60825-1:2007 Safety of laser products

Equipment classification and requirements (identical to

IEC 60825-1 2007)

Sensitivity

2 X 10

-3

mbar.L

-1

Line speed

Up to 500 cpm

Can dimensions

Up to 350 mm (H) by 80 mm (D)

Response time

20 ms

Temperature range

10 — 30 °C (50 — 86 °F)

Sample gas temperature range

Room temperature

Leak detector humidity range

10 to 95 % relative humidity (non-condensing) at 35 °C

(95 °F)

ATEX Approvals (in zone sensor)

Zone 2 Ex II 2G Ex nR II T6 (10 °C

≤

T

amb

≤

30 °C)

(50 °F

≤

T

amb

≤

86 °F)

Leak detection system

CE approved

Protection class

IP65

Hazardous area classification

Ex II 3G Ex nR II T6 (10 ° C

≤

T

amb

≤

30° C)

(50 °F

≤

T

amb

≤

86 °F)

Analog signal out

n/a

Analog signal in

n/a

Digital signal out

3 X normally closed contact

Digital signal in

10/100 Base T ethernet

Inlet gas port connector

¾ in. BSPT

Exhaust gas port connector

¾ in. BSPT

Power supply

120 VAC 60 Hz/240 VAC 50 Hz 200 W/A

Control console size

1,200 x 600 x 560 mm (H x W x D)

Control console weight

70 kg

Sensor head size

590 x 330 x 330 mm (H x W x D) sensor only

Sensor head weight

20 kg (sensor only)

Installation

On production line

System operating voltage

110 — 240 V AC 50 -60 Hz, specify on order

System power consumption

600 W maximum power requirement

Max factory air consumption

25 L/min approximately on regular usage

Factory compressed air pressure

8-10 bar, clean, dry, and oil free

Line space requirement

1.2 m straight free line (maximum)

Air filter particulate filter

2 um, inline filter/regulator required

1.7

Operators’ system pre startup checklist

Remove hose from air line.

Check and bleed air line.

Check filter condition and color before switching on system.

Change filter if more than 60% discolored.

Ensure that there are no cans between the input and output gates.

Power on system.

Power on conveyor; do not let cans though.

Clear any error messages, e.g., encoder.

Purge air in chamber

Let cans through to commence normal working activity.