11

CROSBY

®

STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

• Nozzle ring and guide ring adjustment

The guide ring (10) is the principal blowdown

control ring in the safety valve. To change the

guide ring position, remove the guide ring

set screw (11) from the body (1A). Insert a

screwdriver or similar tool and engage one

of the notches (these can be seen through

the set screw hole).

The guide ring can then be turned to the

right or left as desired. Moving the guide

ring to the right (counterclockwise) raises

it and decreases the blowdown. The guide

ring should never be moved more than

ten notches either way without retesting

the valve.

After each adjustment, always replace,

tighten and lock wire the set screw, being

careful that its point engages a notch.

The nozzle ring (3) is necessary for obtaining

the pop action of the safety valve. This

ring setting is determined at the factory

and rarely needs further adjustment.

Turning the ring to the right

(counterclockwise) raises it and results in a

strong pop action. Blowdown will increase.

Turning the ring to the left (clockwise) lowers

the ring, decreases the blowdown and may

result in warn or simmer if lowered too far.

The range of adjustment of the nozzle ring is

limited and it should not be moved more than

one notch at a time.

The valve performance should be checked

after each adjustment. After each adjustment,

always replace, tighten and lock wire the set

screw, being careful that its point engages

a notch.

Whenever ring adjustments are changed,

a record should be kept of the number of

notches and the direction in which the ring

was moved. This will make it possible to

return to the original setting in case of error.

After the safety valve has been adjusted to

close at the desired pressure, remove the

lifting gear and make sure the adjusting bolt

nut (22) and the set screws (4 and 11) are

installed properly and tightened.

If different ring locations are obtained

after testing, restamp the top of the valve

bonnet (13) with the new (tested) ring settings.

Install the cap assembly (25) according to

Section 10 - paragraph 'Assembly of cap',

making sure there is

1

/

16

” clearance between

the spindle nut (23) and forked lever (30).

Seal wire the cap screws (26) and set

screws (4 and 11).

• Set pressure adjustment

If the safety valve pops before the nameplate

set pressure is reached, or if it does not pop

at the nameplate set pressure, the following

steps for set pressure adjustment should

be taken:

WARNING

Set pressure adjustment should not be made until

the system pressure is 10% to 20% below the

actual popping pressure of the safety valve. The

adjusting bolt should never be turned when the

vessel pressure is near the set pressure of the

safety valve.

- Remove the lever (27), forked lever (30)

and cap (25).

- Loosen the adjusting bolt nut (22).

- If the safety valve has popped below the set

pressure stamped on the valve nameplate,

an increase in set pressure is necessary.

This is obtained by turning the adjusting

bolt (21) clockwise (compressing the

spring). If the safety valve popped above

the nameplate set pressure, decrease

the set pressure by turning the adjusting

bolt counterclockwise (relieving spring

compression).

- After each adjustment, the adjusting bolt

nut (22) should be tightened securely to

prevent loosening of the bolt. The lifting

gear should be reinstalled.

- After the safety valve has been adjusted to

open at the desired pressures, remove the

lifting gear and make sure the adjusting bolt

nut (22) is installed properly and tightened.

Install the cap assembly (25) according to

Section 10 - paragraph 'Assembly of cap',

making sure there is approximately

1

/

16

”

clearance between the spindle nut (23)

and the forked lever (30). Seal wire the cap

screws (26) and set screws (4 and 11).

WARNING

Never make ring adjustments with the vessel

under pressure without gagging the safety valve

properly. Be careful to use only enough torque to

hold the valve closed. Over-gagging may damage

the valve internals.

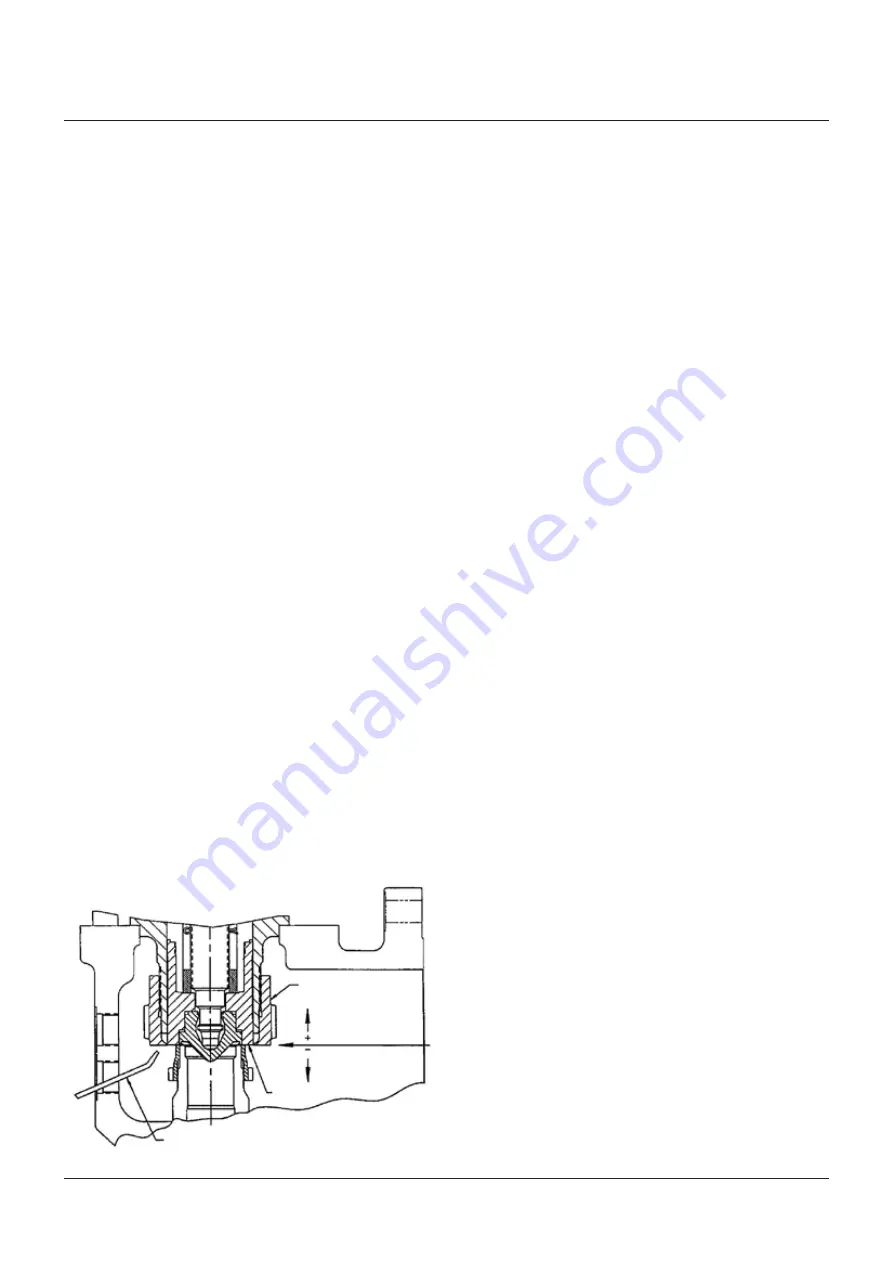

FIGURE 9 - RING SETTINGS AND ADJUSTMENTS

Steel rod to check

guide ring position

* Factory setting of guide ring

position (+/-) notches from

level stamped on bonnet

Disc holder

Guide ring

Level position*

The nozzle ring and guide ring settings are

determined at the factory. Their locations are

stamped on the valve bonnet (13) where the

cap is seated. Adjusting (guide) ring positions

are recorded as plus (+) or minus (-) numbers

from the level position. An illustration of the

guide ring sign convention is presented in

Figure 9. However, if the desired blowdown was

not obtained, it will be necessary to adjust the

rings. The following steps should be taken:

However, in case the guide ring (10) does not

give the desired operating characteristics

under all conditions of operation, the nozzle

ring may be adjusted to control the valve

operation for very fine adjustment. The nozzle

ring is adjusted by removing the nozzle ring

set screw (4) from the valve body (1A).