C6.2.44/0219/E

17

4.2.3 Motor protection

Conventional inherent internal line break motor protection is provided for all ZRD*KRE compressor

models.

4.2.4 Protection devices

Independently from the internal motor protection, fuses must be installed before the compressor.

The selection of fuses has to be carried out according to VDE 0635, DIN 57635, IEC 269-1 or

EN 60-269-1.

4.2.5 Crankcase heaters

IMPORTANT

Oil dilution! Bearing malfunction!

Turn the crankcase heater on 12 hours

before starting the compressor.

A crankcase heater is used to prevent refrigerant migrating into the shell during standstill periods.

Due to the Copeland scroll’s inherent ability to handle liquid refrigerant in flooded conditions a

crankcase heater is not required when the system charge does not exceed the charge limits shown

in

Table 5

.

Compressor

Refrigerant

charge limit

ZRD36KRE & ZRD48KRE

3.6 kg

ZRD61KRE to ZRD92KRE

4.5 kg

Table 5

If a crankcase heater is fitted it is recommended

that the heater be turned on for a

minimum of

12 hours

prior to starting the compressor. This will

prevent oil dilution and bearing stress on initial

start-up. The crankcase heater must remain

energised during compressor off cycles.

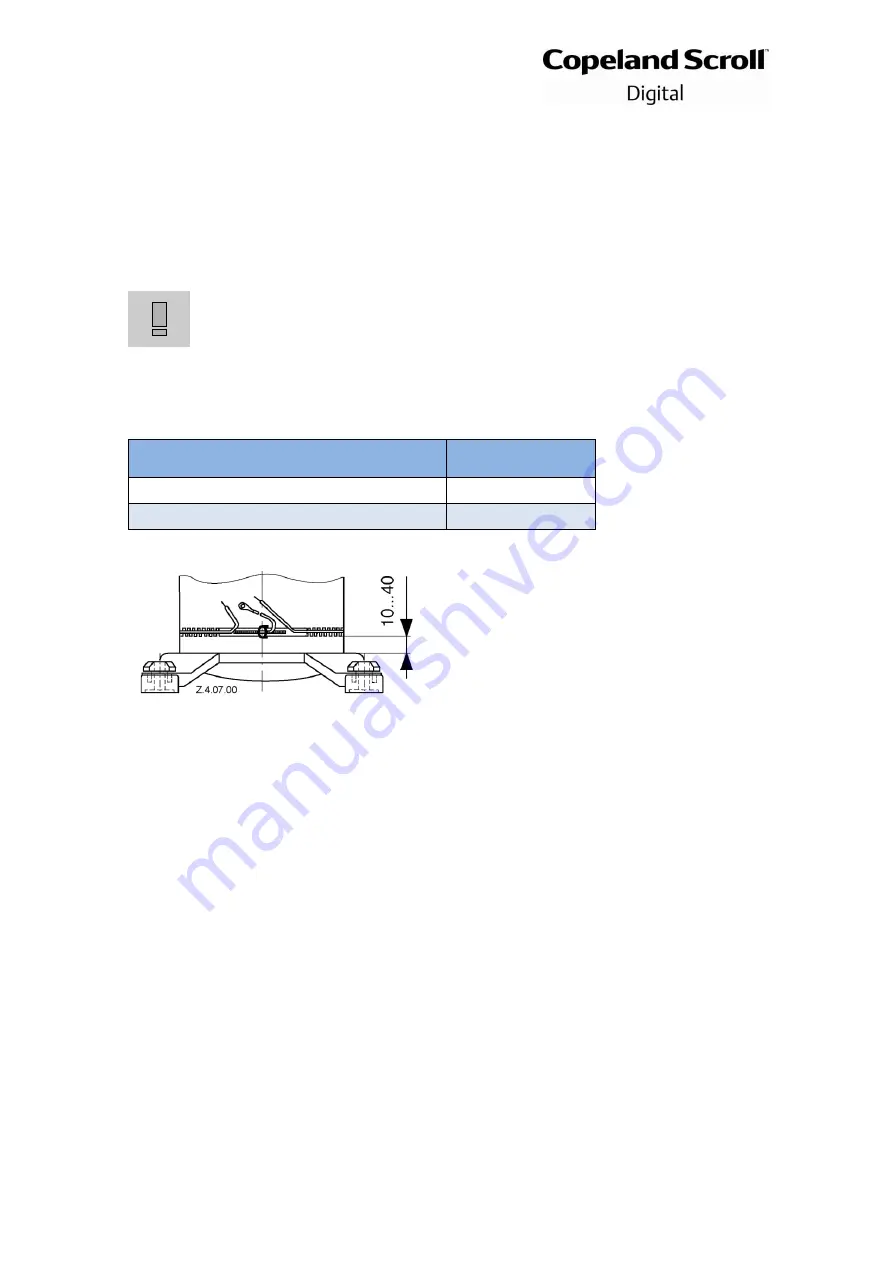

The crankcase heater must be mounted below the

oil Schraeder valve located on the bottom shell

(see

Figure 18

).

The crankcase heater should be wired in such a way that it is turned on whenever the compressor

is switched off.

4.3 Pressure safety controls

4.3.1 IPR valve (Internal Pressure Relief valve)

The internal pressure relief valves for all ZRD*KRE compressors are located between the high

and low sides of the compressor. They are designed to open when the discharge-to-suction

differential pressure exceeds 26-31 bar. When the valve opens, hot discharge gas is routed back

into the area of the motor protector to cause a trip. During developmental blocked fan testing, it is

sometimes noted that the valve opens, but the compressor does not shut off while the discharge

pressure continues to climb. This condition is normally caused by floodback and may be corrected

by using a more restrictive expansion device or reducing the refrigerant charge.

4.3.2 High-pressure control

The cut-out setting for the high-pressure control shall be determined according to regional

standards, usually EN 378, part 2 in Europe.

The maximum pressure value for the individual compressor type, PS high side, is printed on the

nameplate of the compressor.

The high-pressure cut-out should have a manual reset feature for the highest level of system

protection.

Figure 18: Crankcase heater location