C6.2.44/0219/E

9

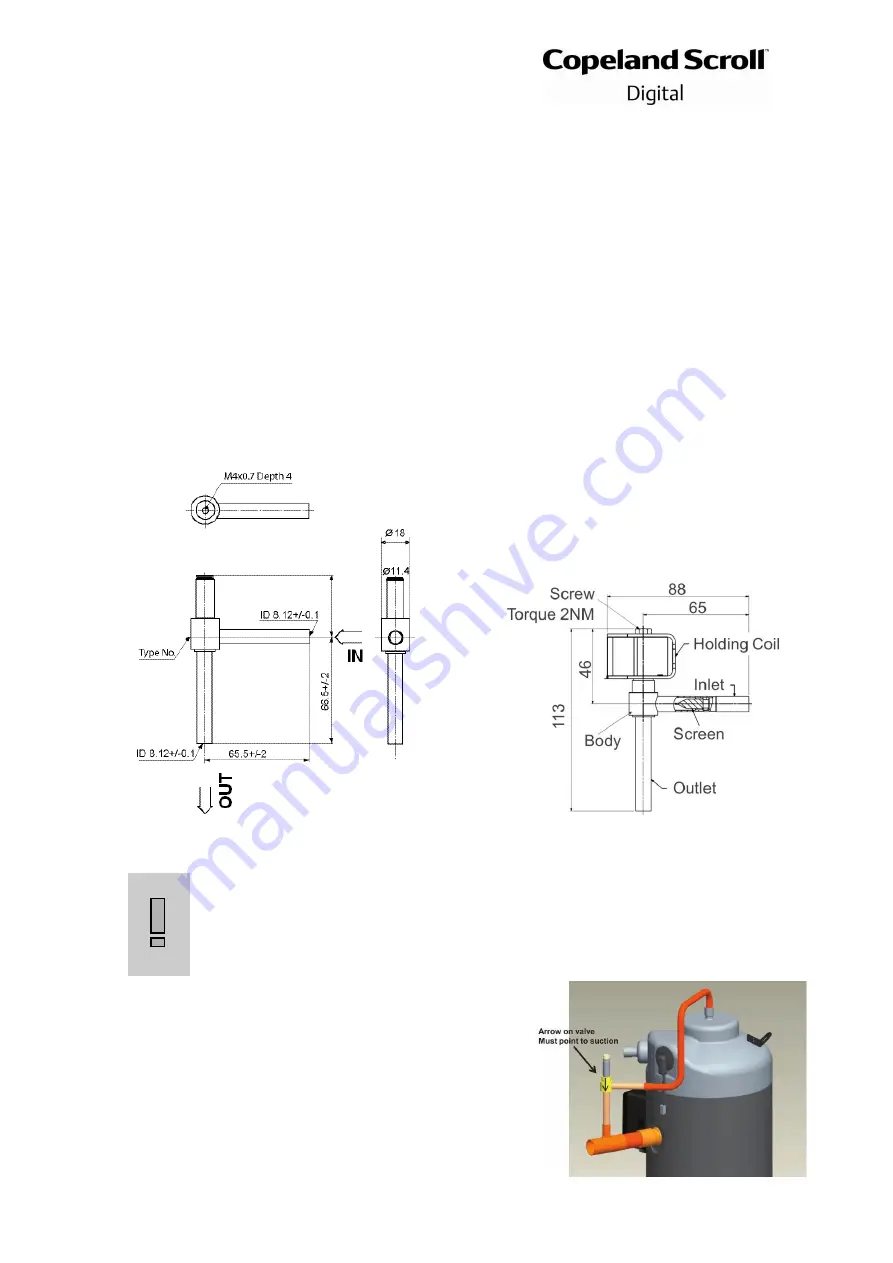

3.2.1 Solenoid valve installation

– General recommendations

▪

The solenoid must be mounted vertically, within ± 15° of vertical. Horizontal mounting is not

permitted.

▪

If a suction Rotalock fitting is used, the threaded shipping plug in the Rotalock fitting must be

removed prior to brazing in the vertical solenoid line.

▪

The valve operation is directional. See

Figure 6

below for inlet and outlet locations.

▪

Do not restrict the line size coming from or leaving the solenoid. Use 3/8" soft drawn copper.

▪

Mount the solenoid valve to the suction line. The tube from the solenoid to the suction should

be as short as possible, less than 3" (76 mm).

▪

From the top cap to the solenoid a series of bends and/or shock loops are required to dampen

vibrations and resonance frequencies the assemblies might see during operation and start-

up. Solenoid tubing mounting kits including solenoid valves are available from Emerson.

▪

The valve body contains a small filter mesh, to avoid large particles entering the inside (see

Figure 7

), which could lead to a defect and blockage. The filter is part of the valve delivery

and already crimped inside; it cannot be changed. This is different from previous valve body

versions, where the filter was delivered loose to the valve body and could be exchanged.

▪

The recommended tightening torque for the screw to fix the coil on the solenoid valve is

2 Nm.

Figure 6: Control valve without coil

Figure 7: Control valve with coil

3.2.2 Solenoid valve installation

– Tubing recommendations

IMPORTANT

This tube has been tested and qualified at 50 and 60 Hz operation for running

stresses and resonance in a single compressor lab environment. However, in

some compressor applications such as racks and transport applications, the

OEM is strongly advised to re-confirm the acceptability of the tube when the

compressor is subject to additional vibration inputs.

The tube from the solenoid to the suction, marked "A",

should be as short as possible (less than 7.5 cm).

Dimensions for a typical tube going from the top of the

compressor are shown in

Figures 8 & 9

.

Figure 8: Recommended piping