CLARKSON

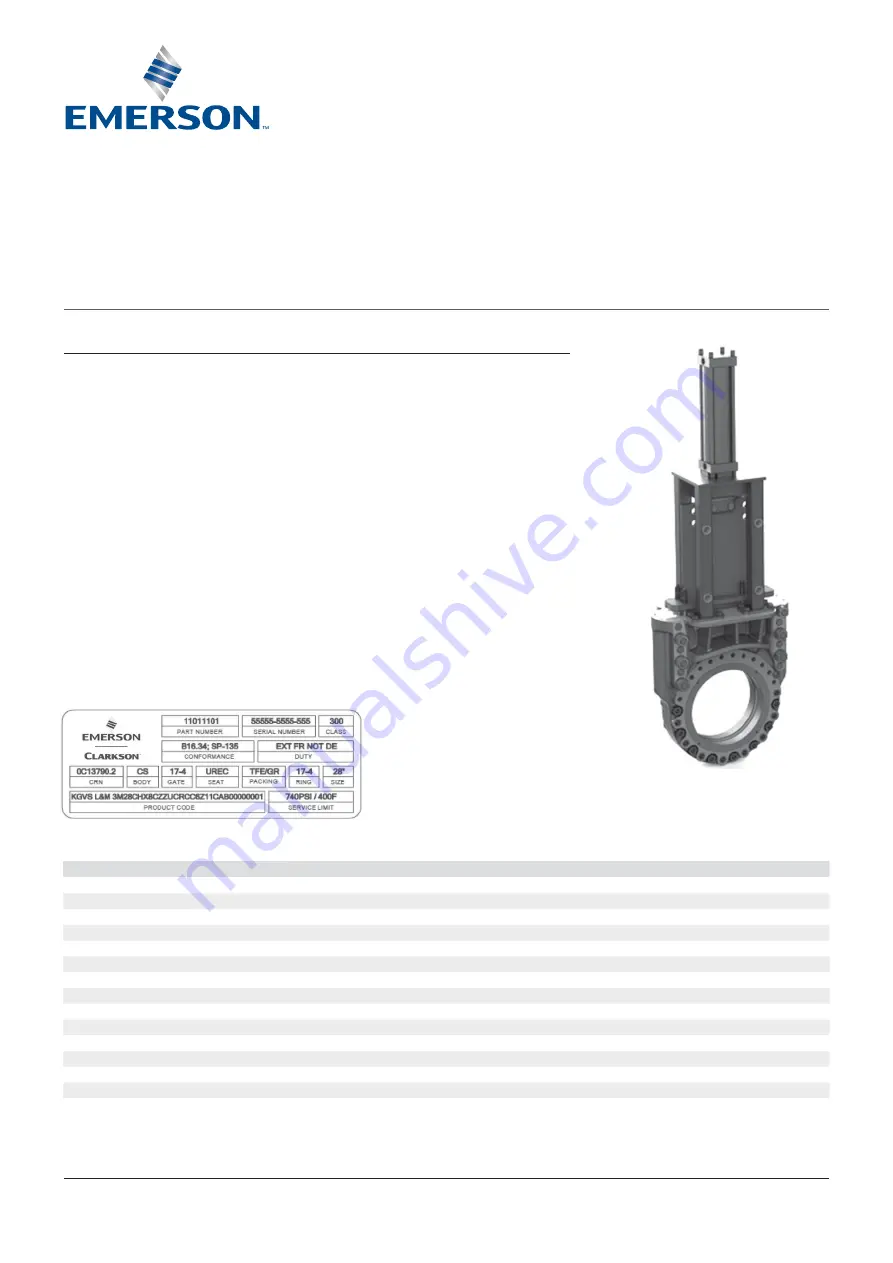

KNIFE GATE VALVE MODEL ZP3OO

INSTALLATION AND MAINTENANCE INSTRUCTIONS

Before installation these instructions must be fully read and understood

GENERAL INFORMATION

LABEL CONTENTS

Item

Description

Example

Product code

Manufacturer’s model/code

KGVS Clarkson 3M28CHX8CZZUCRCC6Z11CAB00000001

Part number

Manufacturer’s pn

11011101

Serial number

Manufacturer’s sn

55555-5555-555

Size

NPS valve size

28

Class

Pressure rating per conforming standard

300

Duty

Type of service depending on valve configuration (ext or int mounted flow ring will change duty) EXT FR NOT DE or INT FR DE

Ring material

Compliance standard for flow ring material

17-4

Service limit

Limits in pressure and temperature operation

740psi/100F

Conformance

Standard used for design and manufacture

ASME B16.34, MSS SP-135

Crn

Canadian registration number

0C13790.2

Body material

Compliance standard for body material

WCB/LCB

Gate material

Compliance standard for gate material

17-4

Seat material

Seat material

URET

Packing material Packing material

TPE/GR

COMPLIANCE LABEL

3. Mating line flanges must be properly

aligned. Slip-on or weld flanges can be used.

Never try to make up for misaligned pipe

flanges by the line bolting.

4. Flange fasteners should be tightened in a

uniform manner using a cross-pattern to

prevent distortion of the valve.

5. Pipe supports and/or expansion joints should

be used to minimize pipe loads on valves.

ZP300 valves are suitable for use in either

vertical or horizontal lines. If installation is

other than vertical, additional support will be

required for cylinder actuated valves.

© 2017 Emerson. All Rights Reserved.

Emerson.com/FinalControl

VCTDS-03757-EN 16/12

The Clarkson ZP300 knife gate valve is

designed to meet extremely rugged and

challenging requirements of expansible fluid

applications in the oil sands processes.

Please take note of specific installation tags

provided with each ZP300 series valve.

1. Compliance to ASME B16.34 Class 300,

Valves-Flanged, Threaded, and Welding End

and MSS SP 135 (Long Face-to-Face).

2. Bi-directional valve, no special concerns

in relation to direction of flow are required

when installing the valve.