24

1

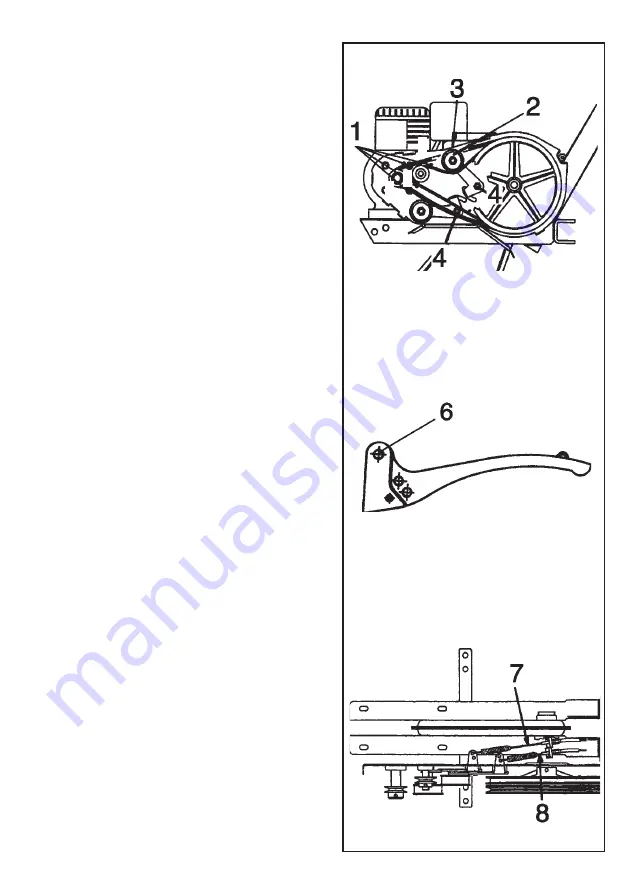

Fig. 9

Fig. 10

Fig. 11

MAINTENANCE

1) Periodically oil joints, control wires

and the belt-tightener support pin.

2) Keep the machine and knifes clean.

3) Periodically, at least once a season,

check the tightness of nuts and bolts,

mainly those concerning the rotary hoe.

To change the oil and service the engi-

ne (spark plugs, air filter, adjustments)

refer to the provided engine handbook.

IMPORTANT WARNINGS

1. After having assembled the belts, che-

ck that these are inside stakes 1 (Fig. 9).

2. In order to avoid great damage to the

rear gear belt, adjust the control wires

in such a way that the external diameter

of the belt-tightener skims the external

profile of bulkhead 2 (Fig. 9).

3. When assembling the belt cover hood,

pull the control levers in order to avoid

the belt from coming out of the pulley

races.

4. Avoid an excessive tightening of nuts

4 as this would cause an incomplete re-

turn of the belt-tightener and consequen-

tly would wear and break the belt.; there-

fore, check that the belt-tightener moves

freely along the whole stroke (Fig. 9).

5. Avoid an excessive tightening of screws

6 as this would prevent the lever return,

loosen if necessary (Fig. 10).

6. Check that the adjusters and the sprin-

gs (for the forward and reverse control) are

assembled according to Fig. 11:

- Forward gear drive control: lever n

°

2

on handlebar (7).

- Reverse gear drive control: lever n

°

7

on handlebar (if applicable) (8).