©

09.02.2006 ELKA-Torantriebe GmbH u. Co. Betriebs KG page 11

EST 204, EST 404, EST 804

11.9.

Alter the force reserve

a) Press the LERN button until Diag LED turns on (approx. 3 s).

b) Press the LERN three times. The Diag LED lights and the SL-LED flashes fast.

c) Press the BT button once to activate alteration of force. The SL-LED turns off and the Diag LED displays

the level of force reserve as sequence of flashing. The higher the number of flashes is, the higher is the

force level. Values between 1 and 16 flashes are possible.

d) Each use of the BT button increases the level about one step. Each use of the LERN button decreases

the level about one step.

e) When the required level is selected, press the BT button, keep on pressing and press the LERN button

once. The new level of force reserve is stored. After this procedure the controller returns to normal

operation mode by itself.

Note:

With every new learning of the running time, the force reserve is set to default (level 6)

11.10.

Set all parameters back to default

a) Press the LERN button until Diag LED turns on (approx. 3 s).

b) Press the LERN four times. The Diag LED flashes fast and the SL-LED lights.

c) Press the BT button once more and

keep on pressing.

The Diag and SL LED light.

d) In addition press the LERN button once. All parameters are set to default. After this procedure the

controller returns to normal operation mode by itself.

Note:

The controller has to be programmed again now.

12.

Operation after power supply break / Emergency mode

When power is switched on, the position of the gate is not known to the controller. Therefore it is only

possible to close the gate until the end position closed is found (gate is pressed against mechanical stopper).

After the position closed is known, the controller changes into normal operation mode.

If a safety device has a malfunction, it is not possible to operate the gate in normal operation mode into the

appropriate direction.

But it is possible to operate the gate in dead man (hold to run) operation using the BT button (external button

fix to terminals BT, or BT button on the controller itself). To activated dead man operation, you press the BT

button keep on pressing for 10 s. During this time the warning light will flash in periods of seconds.

Emergency mode is not possible using the radio remote control.

13.

Error codes MO 56/S

The controller displays certain error codes in case an error is detected. The code is given by the Diag LED.

The Led is flashing several times, makes a break, and repeats flashing several times. To specify the code,

please count how often the LED flashes between two breaks.

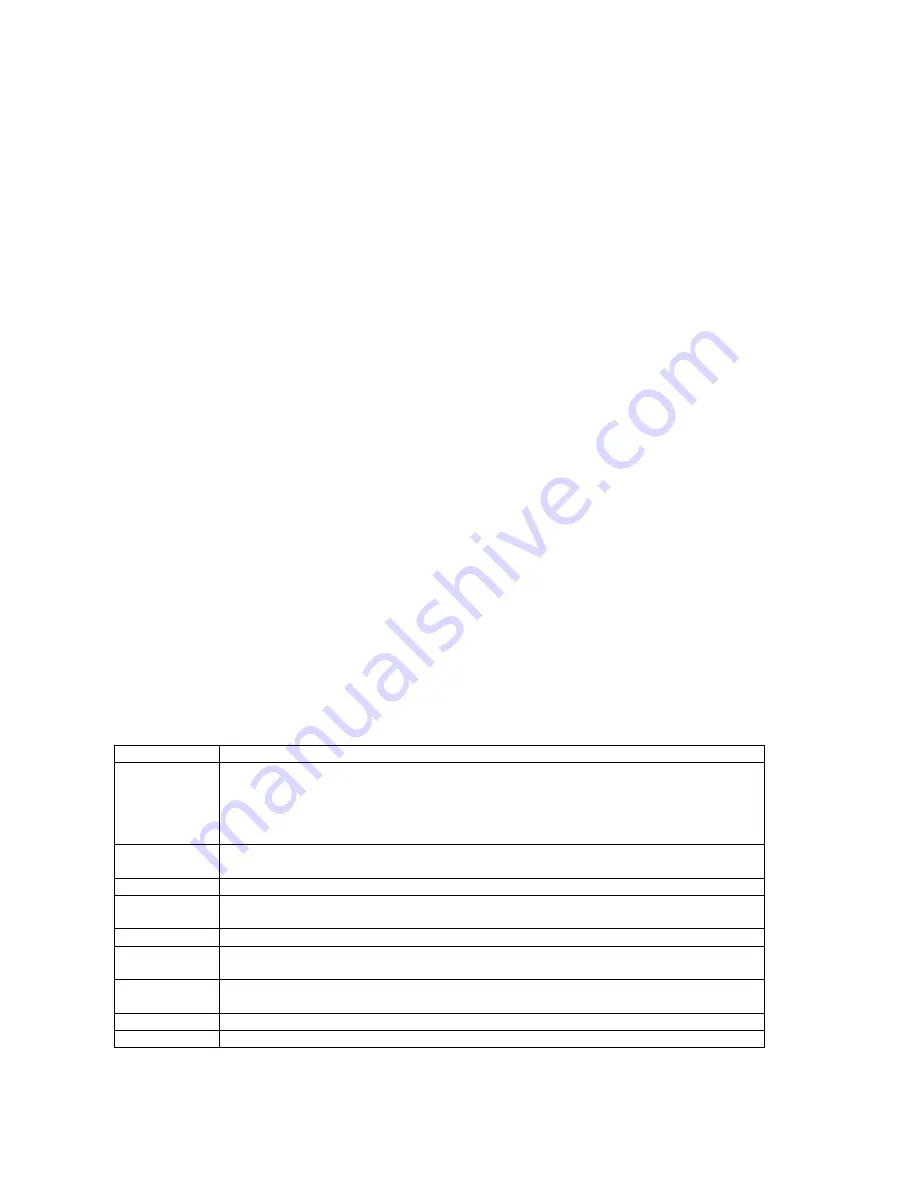

Error code

Reason

1 flash

(flashes non-

stop)

DIP switch error

1. Operation mode has been changed. Confirm with button LERN.

OR

2. The data in the EEPROM and the DIP switches are different. If the error remains

(after 1. – conforming with button LERN) send the controller back to your dealer.

2 flashes

Photocell error. During the photocell test the transmitter was switched off, but the

receiver didn’t report an obstacle.

3 flashes

Safety edge error. During the test of safety edges an error had occurred.

4 flashes

The data in the EEPROM got lost. Try to program again. If the error remains, send

the controller back to your dealer.

5 flashes

The EEPROM can’t be programmed. Send the controller back to your dealer.

6 flashes

TS observation faulty. The controller has got a hardware fault in the redundant TS

observation. Send the controller back to your dealer.

7 flashes

Relay faulty. One of the motor relays doesn’t react. Send the controller back to your

dealer.

8 flashes

Pulse creator (Hall IC) in the motor or cable between motor and controller faulty.

9 flashes

Measuring amplifier faulty. Send the controller back to your dealer.