General installation

487 18 39 01 - 300/500/750 - GB

22

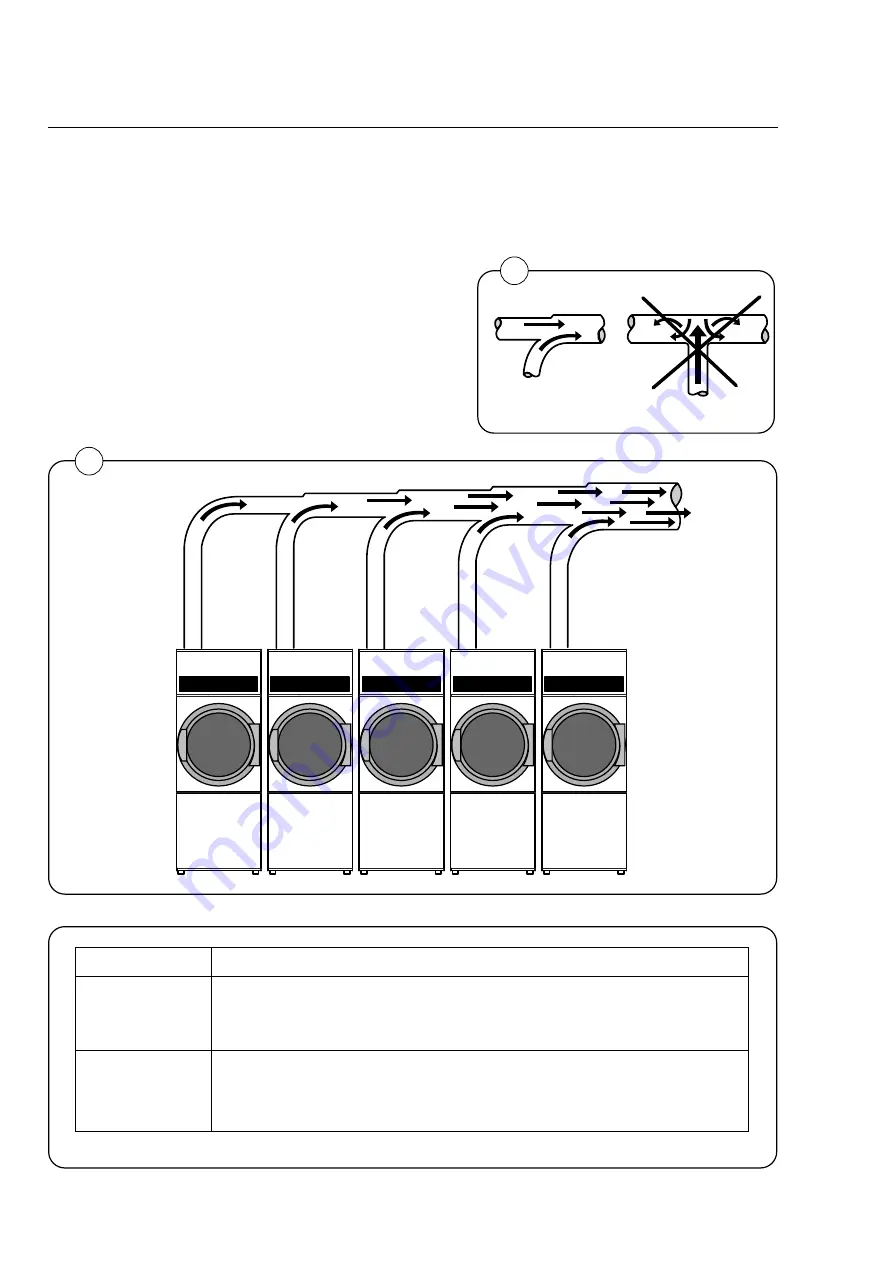

When installing several machines on a shared

evacuation pipe, increase the area of the pipe

with each additional machine so that each

machine will be working at the same air resis-

tance. Fig. 2 and the table show in simplified form

how the evacuation pipe should look.

Note: To keep the air flowing, use bends

(not T-pieces). See Fig. 1.

1

2

3

4

5

6

7

8

9

10

200

280

315

355

400

450

475

500

535

560

0.15

0.30

0.45

0.60

0.75

0.90

1.05

1.20

1.35

1.50

Number of tumble

dryers

Air outlet pipe

diameter, mm

Required area of

fresh-air inlet, m2

Tumble dryer evacuation system

Evacuation system for installation of several machines with

a shared evacuation pipe

1

2

Each machine requires a 400 x 400 mm fresh-air inlet opening.

Summary of Contents for TT300

Page 1: ...Operating and installation manual TT300 TT500 TT750 487 1839 51 01 99 31 ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 18: ...Instructions for use 18 487 18 39 01 300 500 750 GB ...

Page 26: ...General installation 487 18 39 01 300 500 750 GB 26 ...

Page 38: ...Installation electric steam and gas heating 487 18 39 01 300 500 750 GB 38 ...

Page 46: ...Installation electric steam and gas heating 487 18 39 01 300 500 750 GB 44 2 ...