23

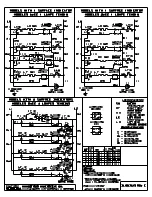

LEVELLING FEET

PENCIL LINE ON THE FLOOR

PLAN VIEW OF THE COOKER

480 mm.

100 mm.

300 mm.

245 mm.

WALL FACE

A

BACK OF COOKER

SIDE VIEW

OF THE COOKER

BASE OF COOKER

ENGAGEMENT EDGE FOR

STABILITY BRACKET

Fig. 3

Fitting the Stability Bracket

(Not supplied)

If the cooker has to be installed with a flexible

supply pipe, it is necessary that a stability device

is fitted.

(See safety Requirements: Page 22).

If a stability bracket is to be fitted by the installer,

these instructions should be read in conjunction

with the leaflet packed with the stability bracket.

Place cooker in its intended position and level

cooker.

Mark off 250 mm (11

1

/

2

") from the right hand

side of the cooker as shown, this is the centre

line of the bracket fixing.

Draw a line 100mm (4") from the front edge of

the levelling feet (see Fig. 2) and remove cooker

from its position. Mark off 480mm (19") back

from this line on the centre line of the bracket to

locate the front edge of the lower bracket.

Fix lower bracket (with two fixing holes) to the

floor, then measure height from floor level to

engagement edge on back of cooker, dimension

'A' of Fig. 2.

Assemble upper bracket to lower bracket so that

underside of bracket is dimension 'A' +3mm (1/

8") above floor level. Re-position cooker and

check that top bracket engages into cooker back

to a depth of 75mm (3"), as shown in Fig. 2.

Should the stability bracket currently installed not

allow the cooker to stand correctly, ask the

installer to replace it with the correct type.

Fig. 2

Connecting to Gas

This cooker is designed to be installed with an

appliance flexible connection. Connection is

made to the RC 1/2 (1/2" B.S.P.) threaded entry

pipe located just below the hotplate level on the

rear right-hand side of the cooker. Check for gas

soundness after connecting the gas supply.

The gas bayonet connector must be fitted in the

shaded area indicated in the diagram. Take into

account that it must be possible to pull the

cooker forward sufficiently. The hose must not

get caught on the stability bracket.

Note:

For certain types of gas bayonet connection

used, it may not be possible for the appliance to

be pushed fully back to the wall stops.

Important:

Flexible tubing MUST comply with BS.669

Current Edition.

FO 2434

FO 2435

600

450

130

Dimensions are given in millimeters

Dimensions are given in millimeters

250 mm.