Technical Support - A.D.L.

54/83

599 74 12-51 Rev.00

11.9.1 AGS

AGS is the abbreviation for the Italian words “

A

lgoritmo di

G

estione dello

S

bilanciamento” (Algorithm of Unbalance

management).

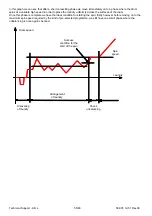

It is a complete procedure for the distribution of the laundry in the drum, limiting the static residual unbalance and

guaranteeing an effective spin phase in an axis subsequently avoiding excessive vibrations in the washing machine.

AGS works properly in all washing machines fitted with a speed sensor and a torque sensor.

The tachometer fitted to the motor sends out the speed signal.

As far as the torque sensor is concerned on the Electronic EWM10 platforms, we have a motor voltage sensor

integrated into the main board that allows us to have an electric power estimate.

Then, via the motor’s efficiency (deducted from a motor load table), we can obtain the mechanical power and lastly the

torque signal:

Low speed

Laundry arrangement

High speed

Spin phase

The AGS control is carried out before each spin and it aims to achieve the following:

-

Measure the inertia moment.

-

Measure the static unbalance.

-

Control the distribution of the laundry load so that the level of static unbalance is below a specific threshold.

-

The dynamics of the unbalance in order to limit the wash unit swings.

-

The calculation of the maximum spin speed with the measured static unbalance.

When all the following conditions are in place, we have the right condition to ensure that the spin can start.

Balanced

laundry

Unbalancing

centre

Balanced laundry

Axis centre