13

For a concentration of 12% the above dosing amount should be multiplied by 3 (i.e. the dose for a 50m³

pool would need to be increased to 960ml/day when the H

₂

O

₂

strength is 12%).

For any other concentration strengths, the dose amount should be adjusted pro-rata as required. The

digital controller will automatically sense the temperature of your water and adjust the required dose

accordingly.

B. Dosing Liquid Chlorine

Refer to table B for suggested Liquid Chlorine dosing figures.

•

TRICKLE DOSING: When dosing liquid chlorine the required daily dosage amount will be

split into multiple intervals within the filtration hours (for example, 420ml will be split into 20

smaller doses. Each dose will be injected for 32 seconds, and they will be equally spaced

throughout a 6-hour period).

•

If a power cut occurs during Trickle Dosing the unit will continue to dose the outstanding

volume once the power has been restored. Please note - the volume that should have

been dosed during the time of the power loss will be skipped.

•

The controller does not monitor the free chlorine level. The pool free chlorine levels must

be regularly checked, and the dosage volume adjusted if required.

.

After selecting ‘CHLORINE’ in Part 1 the display will show ‘CL DOSE’ using the

/

buttons select

the correct dosage volume in ml (millilitres). Once the correct dosage volume is displayed press the O.K

button to confirm, the display will then show ‘CL START’

You now need to enter the time that you would like the CL dosing to take place. Once the correct time is

selected press the ‘O.K.’ button.

NOTE:

•

The time must be entered in the 24-Hour format and the dosing will take place at this time

every day (24-Hours).

•

The time selected must be at a time when the main filtration pump will be running.

•

If the dosing volume for CL period is set to 0.0 (ml) the peristaltic pump will remain off.

Volume of Swimming Pool

(m

3

)

Stabilised Liquid Chlorine

(ml/day)

Dosage is only approximate and

dependant on the exact volume

of your pool, local water type,

temperature, positioning of the

pool

, bather loading, weather,

etc

.

10

200

20

400

30

600

40

800

50

1000

60

1200

Table B

NOTE:

In the event of power loss: the programmed settings (dosing volume and dosing

time) will remain stored. If the power to the controller is switched off for longer than

3-Hours the current time will need to be re-programmed, this is indicated to the

operator by the clock flashing.

Set Current Time

•

To complete the set up you need to programme the current time: Use

the

/

buttons

until

‘SET TIME’ is displayed, Press the O.K. Button.

•

Use

the

/

buttons

as required to select the current time

Summary of Contents for H.R.UV-C SPA-PRO

Page 1: ...H R UV C SPA PRO Installation and Operating Manual HRP 30 SPA ENGLISH...

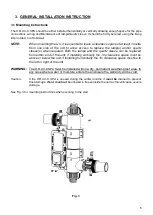

Page 4: ...4 Fig 1 Dimensions...

Page 21: ...21 Notes...

Page 23: ...23...