- 11 -

- 11 -

- 11 -

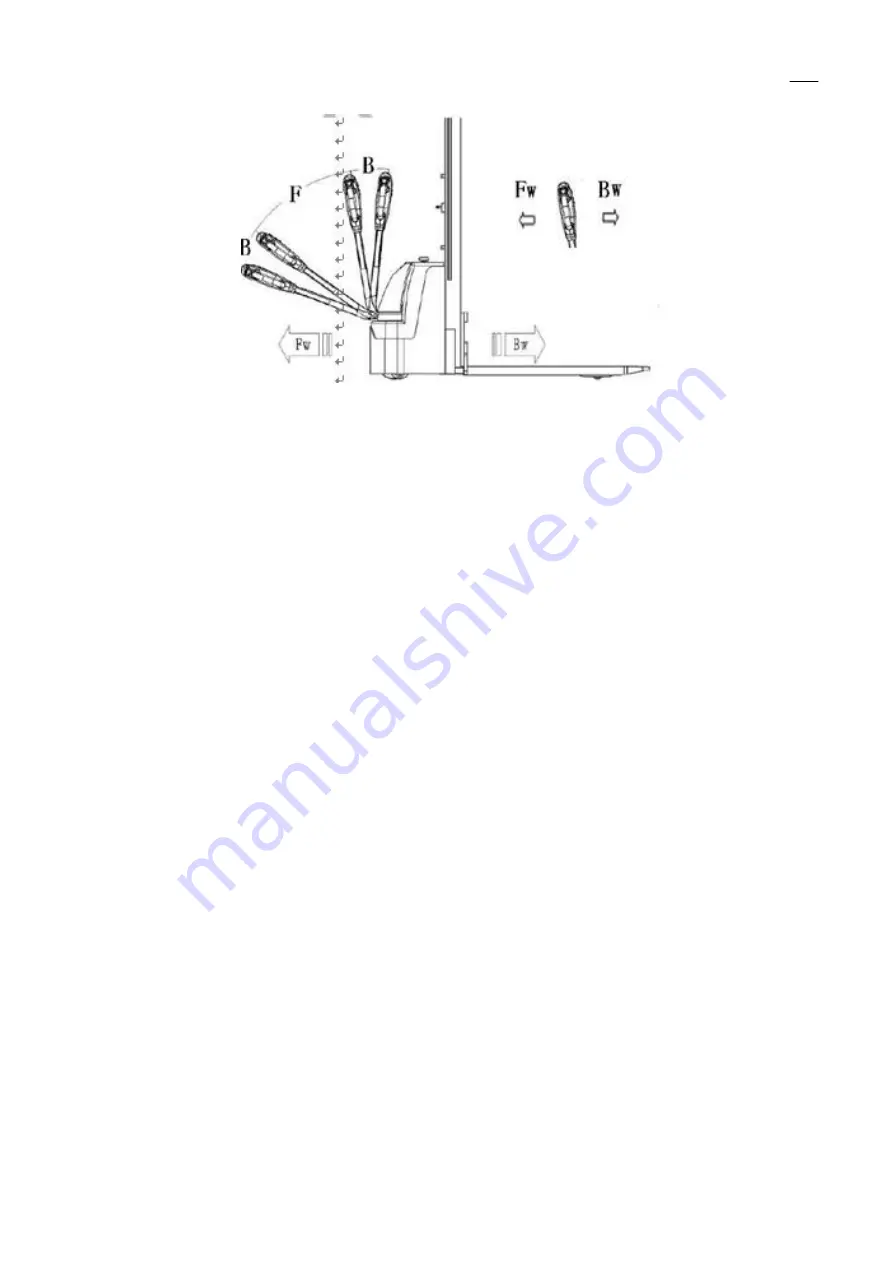

Fig 8: The direction of the operation

5.6. Steering

To move around by the handle for vehicle.

5.7. Brake

Load braking performance depends on the road conditions and vehicle.

Brake function can be activated by the following ways through the accelerator button (12)

moved back to '0' position or the release of this button, the regenerative braking is activated.

Vehicle brake to stop.

Through the accelerator button (12) driving direction move directly to the opposite direction

from a vehicle with regenerative braking, until it began running in the opposite direction.

If the handle is moved upwards or downwards to the braking zone ('B'), vehicle braking. If

the release lever, is automatically moved to the handle braking area ('B'). The vehicle starts

until the parking brake.

Belly switch (14) can prevent the operator by extrusion. If you press this switch, the vehicle

began to slow and / or the beginning of a period of reverse driving distance ('Bw.”), then stop.

If the handle on the operating area and the vehicle is not running, please consider this switch

can also operate on the vehicle.

5.8. Fault

If there is any fault or not operating the vehicle, please stop using the vehicle and press the

emergency stop switch (2).

The vehicle park in a safe area, will be the key switch (16) counter clockwise rotation, and

then pull out the key.

Immediately inform the manager and / or contact your customer service personnel. If

necessary, use a professional lifting equipment will be vehicles from the area of operations.

5.9 In case of emergency