Page 12 of 25

5.2 Stop button

If the

Stop

button is actuated during a current job, the job will immediately be

interrupted and the engraving head will move into the upper right-hand corner of the

device. The red display indicates the interruption. When the button is actuated again,

the engraving arm will be calibrated and the job continued. The red display will go out.

5.3 Delete data memory with Clear Buffer button

If there are data present in the

VE 600

, this will be indicated by the yellow display

lighting up. You can delete these data by using the

Clear buffer

button. To do this, the

device must be in Stop mode (red display illuminated).

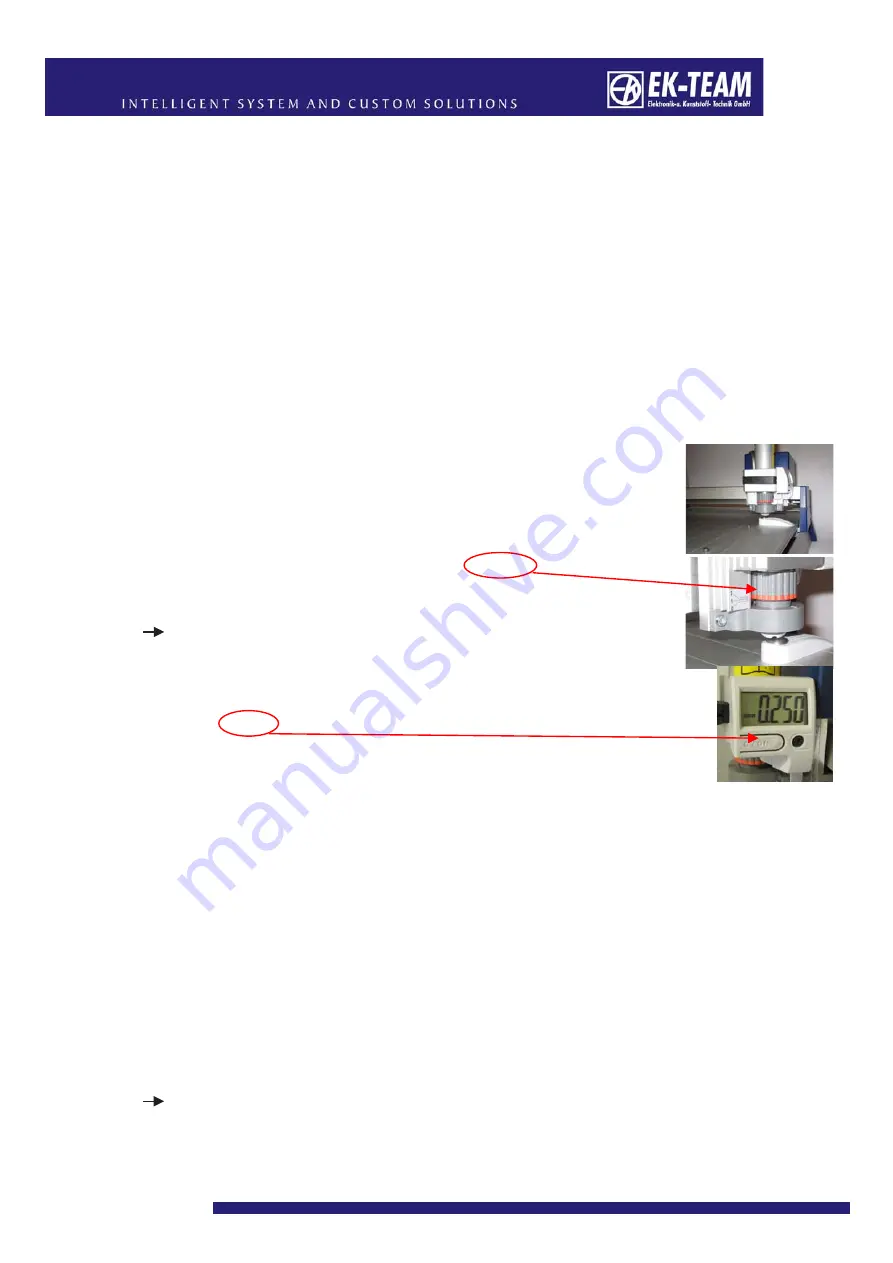

5.4 Norm button (standardisation of the engraving needle, zero setting)

If the

Norm

button is actuated, the engraving head will move to the

position (bottom right of the device) beneath which a contact

surface is located, and the engraving head will be lowered slowly.

As soon as the engraving needle reaches the contact surface, the

lowering of the engraving head will stop and an audible

signal will be issued. Now turn the depth adjuster to the left until the

audible signal stops.

This sets the engraving needle to the “zero position.”

Note:

If there is no audible signal when the engraving head is

lowered, turn the depth adjuster to the right until the signal does

sound. Then turn it by one latch engagement position to the left.

The signal will go out and the “zero position” is set.

Press the button in order to zero the nos. of the indicator.

5.5 HIGH / LOW rotational speed of engraving spindle

When engraving data are transferred from the PC to the engraver, the

rotational speed of the engraving spindle will also be automatically transferred. If you

want to change these data during the engraving process, you can change the speed

by means of the appropriate buttons.

Actuation of the

HIGH

button will increase the engraving spindle speed 5000 rpm

(revolutions per minute), and actuation of the

LOW

button will reduce it by 5000 rpm.

5.6 HIGH / LOW engraving speed

When engraving data are transferred from the PC to the engraver, the engraving

speed will also be automatically transferred. If you want to change these data during

the engraving process, you can change the speed by means of the appropriate

buttons.

By actuating the

HIGH

button, the engraving speed will be increased by

2 mm/sec., and by actuating the

LOW

button it is reduced by 2 mm/sec.

Note:

The adoption of the speed change takes place with a slight delay.