37

Attachments with chain drive

409001_01 | 12.2020

Declaration of conformity

The manufacturer:

Eder Mechanical Engineering GmbH

Schweigerstraße 6

38302 Wolfenbüttel

Germany

Herewith declares that the machine designated below complies with the relevant essential safety and

health requirements of the EC Machinery Directive 2006/42/EC due to its design and construction.

Main designation:

EDER Bark Stripper ESG-C Serial number: ESG-C001000

Alternative accessories: EDER Flat Planer EPH-C

Serial number: EPH-C001000

EDER Curved Planer ERH-C

Serial number: ERH-C001000

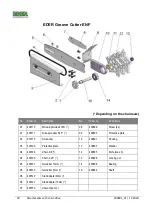

EDER Contour Planer EKH-C Serial number: EKH-C001000

EDER Wire Brush ERB-C

Serial number: ERB-C001000

EDER Groove Cutter ENF-C

Serial number: ENF-C001000

EDER Bark Beetle Cutter EBF-C Serial number: EBF-C001000

and following

The following standards were used to implement the safety and health requirements specified in the EC

directives:

1. EN ISO 12100, Safety of machinery - General principles for design, risk assessment and risk reduction

2. Centrifugal force test according to DIN EN 847-1, Machine tools for woodworking - Safety requirements

- Part 1: Milling and planing tools, circular saw blades

Internal measures have been taken to ensure that the serial production devices always meet the

requirements of the current EC directives and the standards applied.

Authorized person for the technical documentation: Michael Pögel

Wolfenbüttel, 10.08.2020

Ulrich Schrader, Managing Director